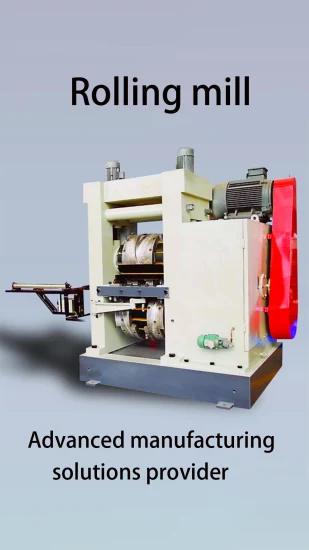

Automatic Transverse Forging Rolling Mill Hot Rolling Mill for Sale China Supplier

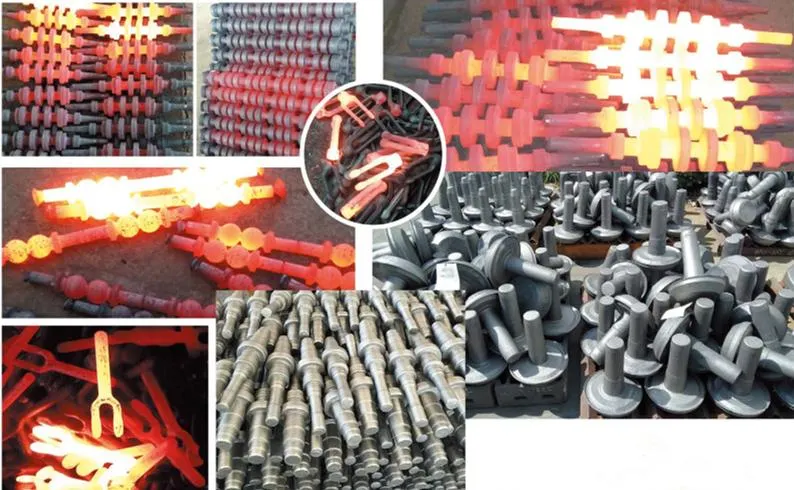

Product display Cross wedge rolling refers to the continuous local deformation of the cylindrical billet between the die

Description

Basic Info

| Model NO. | D46-1200 |

| After-sales Service | Provide |

| Warranty | One Year |

| Roller Position | Special Form |

| Roller Number | Universal |

| Layout | Staggered |

| Type | Hot Rolling Mill |

| After Service | Local Service After Sale in India and Vietnam |

| Max Rod Dia | 120mm |

| Max Rolling Length | 1000mm |

| Mould Width | 1200mm |

| Rolling Diameter | 1000mm |

| Transport Package | Plywood Case |

| Specification | 6550*2800*4500 |

| Trademark | Ubright |

| Origin | Cn |

| HS Code | 8474801000 |

| Production Capacity | 100 Sets/Month |

Product Description

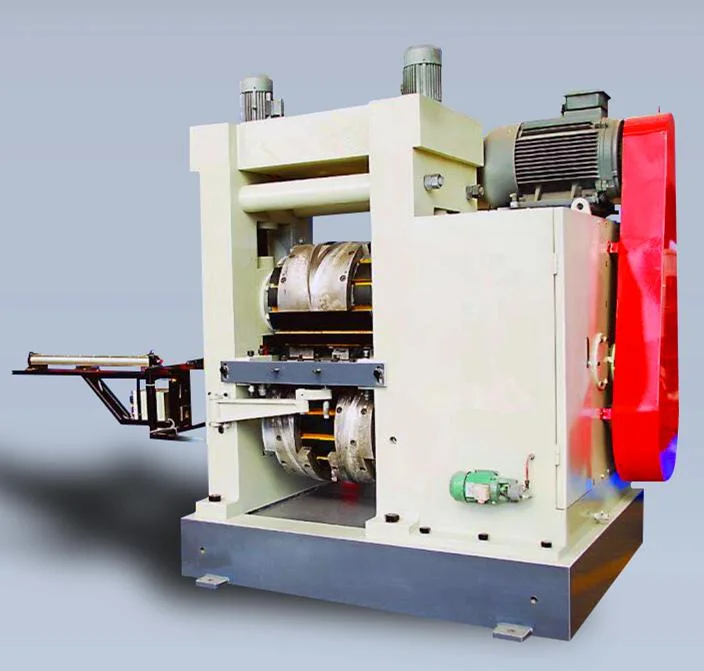

Product displayCross wedge rolling refers to the continuous local deformation of the cylindrical billet between the dies of two rolls, which results in the shape of the workpiece and the bottom of the die Partial grooves have the same shape. The type module is mounted on a roller and rotates in the same direction under the drive of the roller to drive the round billet Rotating in the opposite direction, the billet compresses and deforms in the radial direction of the wedge. The shape of the rolled workpiece and the bottom groove of the die Consistent.

Machine Feature:

The working environment has been improved: Because there is no impact and little noise in the process of cross wedge rolling, its working environment has been greatly improved.High production efficiency: It is usually 2-5 times more than other processes. One or two pieces can be designed according to the different work pieces.Good product quality: The metal fiber streamline of cross wedge rolled piece is continuously distributed along the product shape, and the grain size is further refined, so its synthesis machine Mechanical performance is better, the product accuracy is also high.High material utilization rate: Because the shape of the rolled workpiece is consistent with the shape of the groove at the bottom of the die, the size of the workpiece can be well controlled to improve the material utilization rate. The general material utilization ratio is relative to this He improved traditional techniques by 10-30%.High degree of automation: The feeding, forming, surface finishing and finally rolling forming of the workpiece are all completed by the machine automatically, without human operation.Improve the life of forging die: The general accuracy of the cross wedge mill can be controlled in about ±1mm. And the consistency of the workpiece is high. The uniform force on the regular forging die improves the service life of the forging die

Product Paramenters

| Parameters | D46-300 | D46-400 | D46-500 | D46-630 | D46-800 |

| Max rod dia | 32 mm | 45 mm | 55 mm | 65 mm | 85 mm |

| Max rolling length | 260 mm | 300 mm | 400 mm | 500 mm | 600 mm |

| Reduction rate of primary section of rolled piece | <75 % | <75 % | <75 % | <75 % | <75 % |

| Normal rolling temperature | 1050-1150 °C | 1050-1150 ºC | 1050-1150 ºC | 1050-1150 ºC | 1050-1150 ºC |

| Outside diameter of die sleeve | 320 mm | 400 mm | 500 mm | 630 mm | 800 mm |

| Mould width | 400 mm | 500 mm | 500 mm | 600 mm | 900 mm |

| Rolling diameter | 240 mm | 320 mm | 400 mm | 500 mm | 640 mm |

| The length of the rolling | 450 mm | 500 mm | 500 mm | 600 mm | 900 mm |

| Rolling speed | 28 r/min | 25 r/min | 15 r/min | 12 r/min | 7-9 r/min |

| Radial adjustment of upper roll | ±15 mm | ±15 mm | ±25 mm | ±30 mm | ±35 mm |

| Axial adjustment of rolling roll | ±6 mm | ±8 mm | ±10 mm | ±10 mm | ±10 mm |

| Roll phase adjustment Angle | ± 3 ° | ± 3 ° | ± 3 ° | ± 3 ° | ± 3 ° |

| Adjustment of guide plate up and down | ±15 mm | ±20 mm | ±20 mm | ±30 mm | ±35 mm |

| Adjustment of guide plate front and back | 20 mm | 30 mm | 30 mm | 30 mm | 30 mm |

| AC motor | Y160L-4 | Y180L-4 | Y225M-6 | Y280S-6 | Y315S-6 |

| Power | 15 KW | 22 KW | 30 KW | 37 KW | 55 KW |

| Speed | 1450 r/min | 1450 r/min | 970r/min | 970 r/min | 970 r/min |

| Gear box | DH300 | DH400 | DH500 | DH630 | DH800 |

| Reducer transmission ratio | 19.89:1 | 25.39:1 | 32.8:1 | 33.8:1 | 63.5:1 |

| Dimention(L/W/H) | 1900×1170× | 2000×1420 | 2500×1600 | 3800×1750 | 4420×2200 |

| 1600 mm | ×1670 mm | ×2100 mm | ×2650 mm | ×3100 mm |

| Parameters | D46-1000 | D46-1000(Heavy type) | D46-1200 | D46-1200(Heavy type) | D46-1400 |

| Max rod dia | 100 mm | 110 mm | 120 mm | 130 mm | 150 mm |

| Max rolling length | 900 mm | 900 mm | 1000 mm | 1000 mm | 1150 mm |

| Reduction rate of primary section of rolled piece | <75 % | <75 % | <75 % | <75 % | <75 % |

| Normal rolling temperature | 1050-1150 ºC | 1050-1150 ºC | 1050-1150 ºC | 1050-1150°C | 1050-1150°C |

| Outside diameter of die sleeve | 1000 mm | 1000 mm | 1200 mm | 1200 mm | 1400 mm |

| Mould width | 1000 mm | 1000 mm | 1200 mm | 1200 mm | 1200 mm |

| Rolling diameter | 800 mm | 800 mm | 1000 mm | 1000 mm | 1100 mm |

| The length of the rolling | 1000 mm | 1000 mm | 1200 mm | 1200 mm | 1200 mm |

| Rolling speed | 4-6 r/min | 4-6 r/min | 3.5-4.3 r/min | 3.5-4.3 r/min | 4 r/min |

| Radial adjustment of upper roll | ±50 mm | ±50 mm | ±55 mm | ±55 mm | ±65 mm |

| Axial adjustment of rolling roll | ±10 mm | ±10 mm | ±10 mm | ±10 mm | ±10 mm |

| Roll phase adjustment Angle | ± 3 ° | ± 3 ° | ± 3 ° | ± 3 ° | ± 3 ° |

| Adjustment of guide plate up and down | ±45 mm | ±45 mm | ±50 mm | ±50 mm | ±40 mm |

| Adjustment of guide plate front and back | 40 mm | 40 mm | 40 mm | 40 mm | 50 mm |

| AC motor | Y315L1~6 | Y315L2~6 | Y315L2-6 | Y355M1-6 | Y355M2-6 |

| Power | 110 KW | 132 KW | 132 KW | 160 KW | 185 KW |

| Speed | 970 r/min | 970 r/min | 970 r/min | 970 r/min | 970 r/min |

| Gear box | DH1000 | DH1100 | DH1200 | DH1300 | DH1400 |

| Reducer transmission ratio | 50:01:00 | 50:01:00 | 78.8:1 | 78.8:1 | 82.5:1 |

| Dimention(L/W/H) | 5830×2750 | 5830×2750 | 6550×2800 | 6550×2800 | 6800×3000 |

| ×3950 mm | ×3950 mm | ×4500 mm | ×4500 mm | ×5000 mm |

Our Contact

Send now