China Factory Price Dry Wire Drawing Bench Machine for Construction Carbon Steel Wire with Rotary Die Box

Automatic Drawing Bench 1. Description of draw bench The hydraulic automatic draw bench applies to draw forming and leng

Description

Basic Info

| After-sales Service | Engineer Guide |

| Warranty | 2 Years |

| Type | Coating Production Line |

| Coating | Plating |

| Substrate | Copper |

| Certification | CE, RoHS |

| Condition | New |

| Control | Speed Digital Display |

| Price | Competitive |

| Feature | High Strength |

| Advantage | High Capacity |

| Applicable Industries | Manufacturing Plant |

| Raw Material | Aluminum Copper Scrap |

| Weight (Kg) | 20000 |

| Color | Customized |

| Separation Rate | 93.6% |

| Usage | Tin Slag Recycling |

| Capacity | 100kg-15t |

| Rolling Type | Continuous Rolling |

| Voltage | Onsite Condition |

| Electrical Components | Chint or Other Quality Components |

| Transport Package | Carton Box or Wooden Box |

| Specification | 2300CM*2500CM*2300CM |

| Trademark | Holland |

| Origin | Beijing |

| Production Capacity | 3000 Set/Sets Per Year |

Product Description

Automatic Drawing Bench

1. Description of draw bench

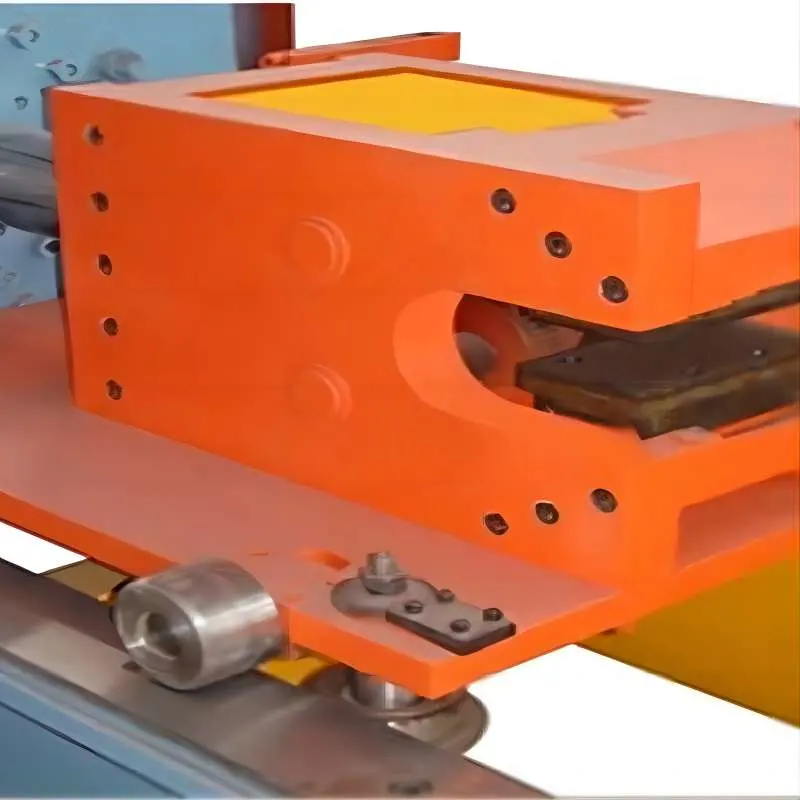

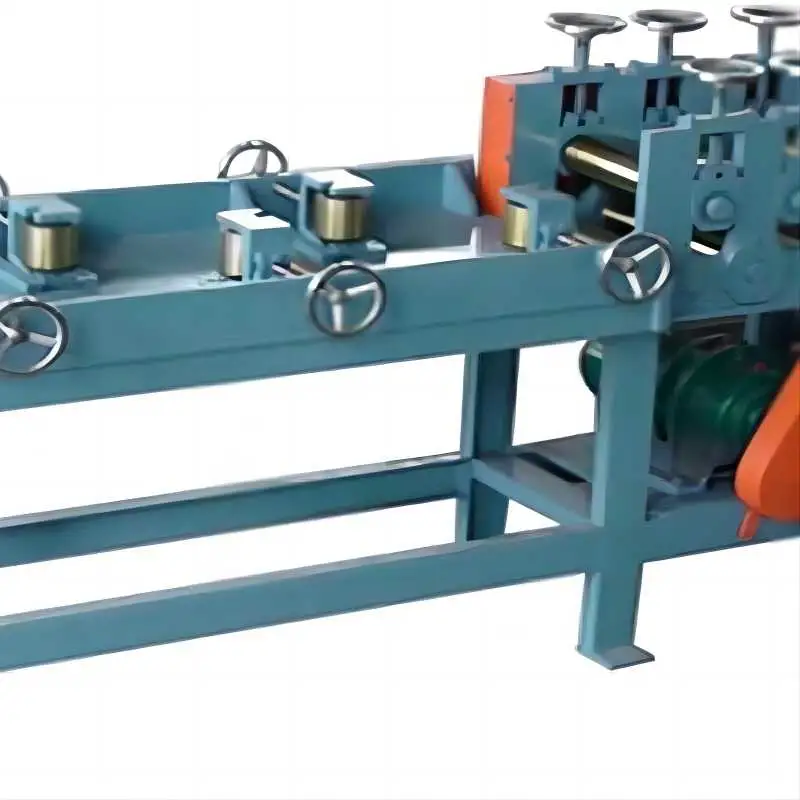

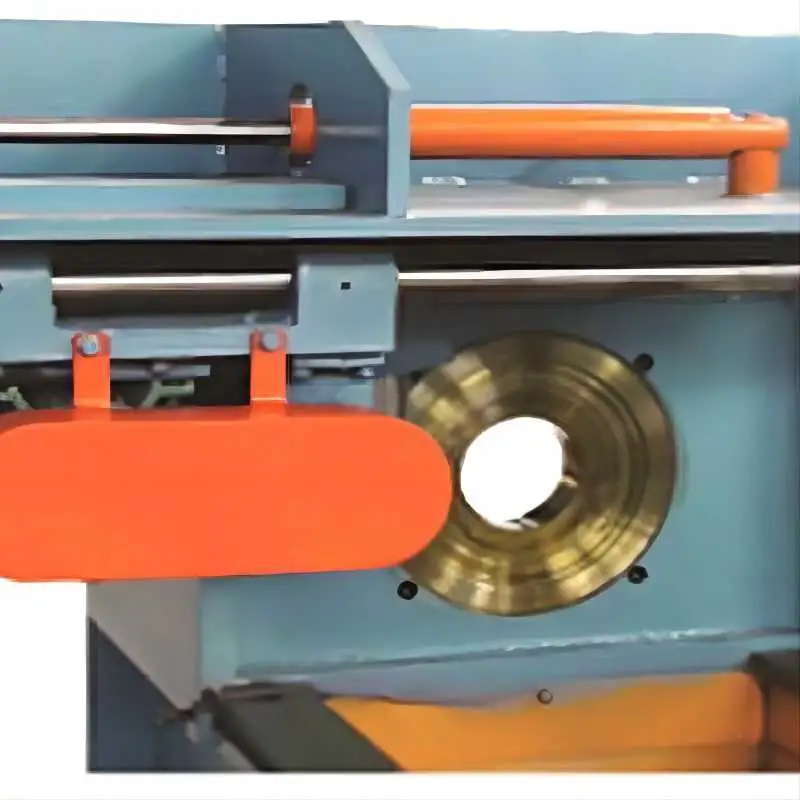

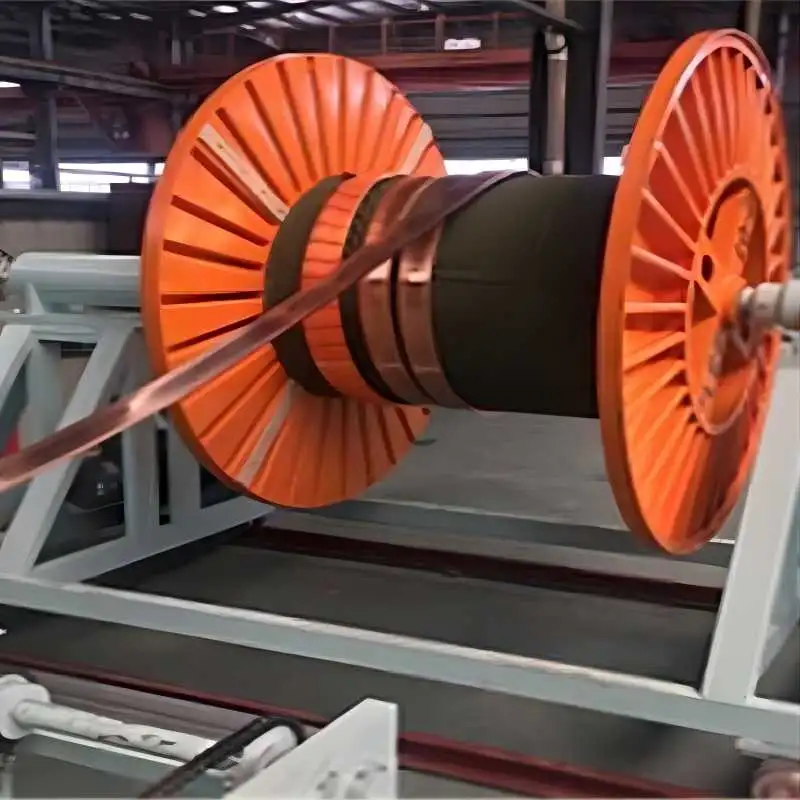

The hydraulic automatic draw bench applies to draw forming and length cut of the copper busbar after extruding, The drawn copper bar has stable cross-sectional size, good dimensional accuracy, improved hardness, elastic limit and conductivity, and at the same time the machine increases the material utilization and greatly improves the surface quality of copper busbar.

2. Main technical parameters

| 1 | Model | YLB()-50-10 | ||

| 2 | Nominal drawing capacity | 50t | ||

| 3 | Effective drawing length | 10m | ||

| 4 | Specification of copper bar | Width | Max 200mm | |

| Thickness | 3~20mm | |||

| 5 | Drawing speed | 3~17m/min (the speed is up to 17m/min under low pressure) | ||

| 6 | Return speed | 50m/min | ||

| 7 | Install capacity | 125KW | ||

| 8 | Compressed air | 0.8Mpa, 2m3/h | ||

| 9 | Consumption of cooling water | 30m3/h | ||

| 10 | Power supply form | Three-phase four-wire | ||

| 11 | Dimension | Length (mm) | 23000 | |

| Width (mm) | 4500 | |||

| Height (mm) | 2200 | |||

| 12 | Requirements of the length of the workshop (mm) | 36000×5000 | ||

3. Main component

3.1. Pay-off stand 3.2 Guide stand 3.3 Straightening and feeding machine 3.4 Cooling and lubricating system of die 3.5 Main drawing machine 3.6 Transport mechanism3.7 Final product cutting machine 3.8 Fix-length roll table3.9 Stacking device 3.10 Hydraulic system3.11 Electrical control system3.12 Pointing machine

Our Contact

Send now