CNC High Speed Copper Wire and Steel Wire Straightening and Cutting Machine for 0.1-0.8mm

Overview Detailed Photos CNC high speed copper wire and Steel Wire Straightening and Cutting Machine for 0.1-0.8mm https

Description

Basic Info

| Model NO. | 0.1-0.8mm |

| Certification | ISO9001, CE |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| Transport Package | Wooden |

| Specification | 2300mm× 600mm× 1280mm |

| Trademark | Qipang |

| Origin | Shanghai |

| HS Code | 0701900000 |

| Production Capacity | 1000units/Mouth |

Product Description

Detailed Photos

CNC high speed copper wire and Steel Wire Straightening and Cutting Machine for 0.1-0.8mm

https://shqipang.en.made-in-china.com/contact-info.html

Product Parameters

| · 1.Applicable wire diameter | 1.0-6.0mm |

| · 2. Length tolerance | ±0.2mm |

| · 3. Straightening speed | 18 m/min |

| · 4. Motor power | 0.75 kw *2 sets |

| · 5. Rated voltage | 380V |

| · 6. Size | 1800 * 690* 760 mm (length * width * height) |

| · 7. Weight | 250kg |

| · 8. Material requirements | coiling wire |

| · 9. Mechanical features | Chinese-English menu, super LCD, easy to operate. |

| · 10. Set the number of times, accumulate quantity and memory of specifications. | |

| · 11. The cutting length is adjustable and is controlled by PLC program. | |

https://shqipang.en.made-in-china.com/contact-info.htmlsteel wire straightening and cutting machine iron wire straightening machine

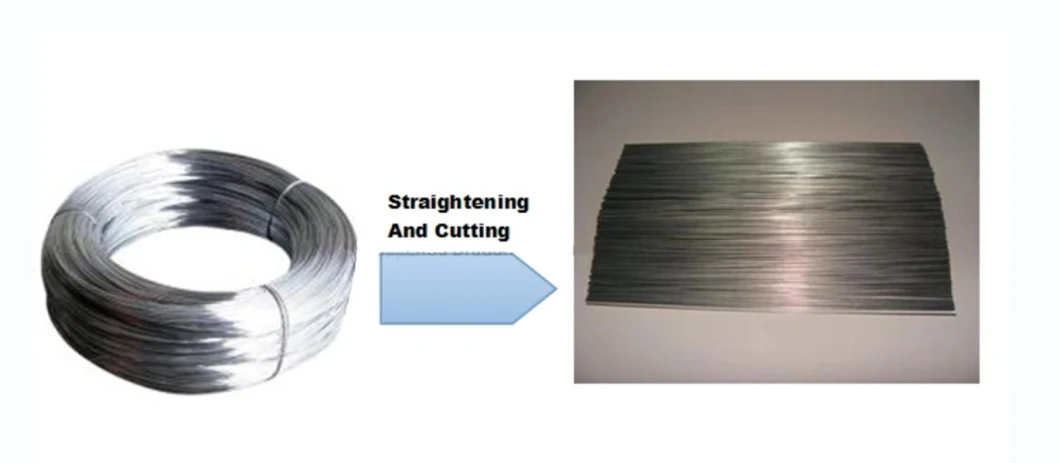

Cutting effect display Our cutting machine is suitable for 1-6mm, not a machine can meet 1-6mm wire at the same time, different sizes of wire need to change abrasive tools.

Product Tour

Factory Tour

The operating instructions:

1.Before the machine works, it is necessary to inject about three-quarters of the hydraulic oil into the hydraulic tank (the hydraulic oil will overflow when the machine is too full), and at the same time, inject oil into the oil hole to lubricate all parts. 2. Connect the power supply (380V, 5 wires, 3 live wire, black is the neutral line, the two colors wire are the ground line), turn on the power switch, the display will light, see if the direction of the motor is going forward, click on the jog whether the switch machine is working properly. 3. The screen shows the length of the wire (is the length of your product), other data has been debugged before leaving the factory. Please do not arbitrarily change, first press [SET], there will be a black block, then you can adjust the data, [ENT] is the confirmation button, [ALM] is the output is cleared. 4. The iron wire passes through the 2 sets of straightening wheels from the wire frame all the way to the incision. Press the screw, press the hoe, press the jog feed line, and press the jog switch to straighten the cut and connect. Then open the automatic switch and you can work continuously. Certifications

About us

Shanghai Qipang industrial co., LTDWe are producing and selling: rolling ring drives, linear drives, linear drives nut, wire straightener, automatic wire straightening and cutting machine, automatic coiling & packaging machine, drawing and rolling machine, automatic yarn winding machine and accessories for rolling ring drives.

straightening cutting wire machinewire straightening cutting machine CN4-6mm

CNC high speed copper wire and Steel Wire Straightening and Cutting Machine for 0.1-0.8mm

Prev: Fast Automatic Straightening & Cutting Machine for 5-12mm Bar

Next: CNC Control High Speed Steel Wire Straightening and Cutting Machine

Our Contact

Send now