Copper Rod Breakdown with Annealing Production Line

Copper Rod Breakdown with Annealing Production Line. 1.Description: Produce copper wires sized φ1.2-4.5mm from aluminum

Description

Basic Info

| Control Type | PLC |

| Customized | Customized |

| Condition | New |

| Automatic Grade | Automatic |

| Type | Pelletizing |

| Plastic Processed | PP, PE, PVC, Rubber |

| Product Type | Granulating Extruder |

| Feeding Mode | Multiple Feed |

| Assembly Structure | Integral Type Extruder |

| Transport Package | Wooden Package or Customized |

| Specification | Customized |

| Trademark | Reliable |

| Origin | China |

Product Description

Copper Rod Breakdown with Annealing Production Line.1.Description:

Produce copper wires sized φ1.2-4.5mm from aluminum rods of φ8mm , Wire online annealing softening;

According to customer needs to provide 9, 11, 13 die wire-drawing machine;

It provides two kinds of equipment, namely single-motor drive and sub-motor drive, and single-head and double-head equipment, which are more than two kinds of drives.

Optional:Single take-up machine, double automatic take-up machine, vertical pay-off machine or their combination of various take-up forms;

Using MMI+PLC control system, production line synchronization control, online monitoring, process parameters can be modified in the touch screen, storage, reading, simple and fast operation;

The machine is completed with other items which can be supplied by Reliable upon customer's request, such as heading press machine, heat exchanger, vapor generator, filter unit for drawing solution, etc.

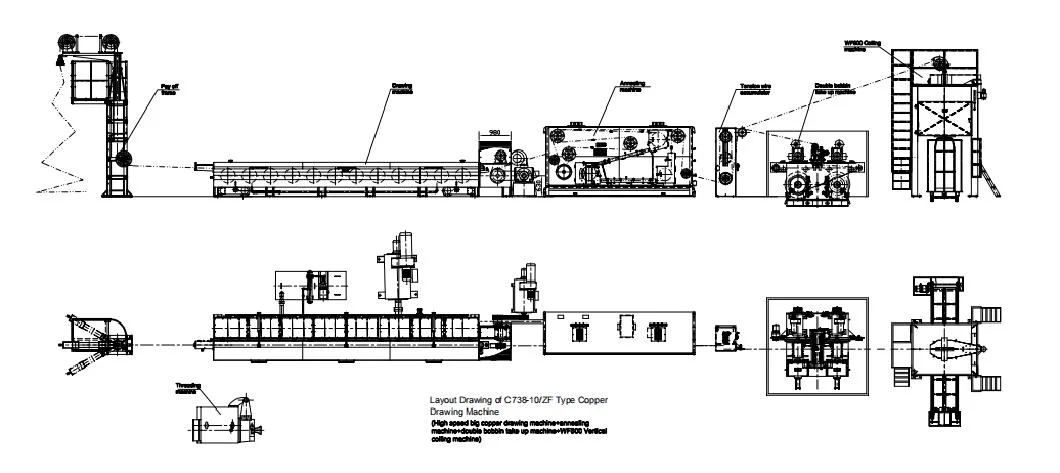

2.Equipment Pictures:

Rod breakdown technical specifications

3.Technical Parameters:

| Drive Mode | Model | Inlet Dia (mm) | Wires | Outlet Dia (mm) | Max.Speed (M/S) | Max Drawing Pass | Capstan Dia(mm) | Installed Capacity (kVA) | Take-Up Type(Optional) |

| Shunt Drive | LWHD-450/9 | Φ8 | 1 | Φ2.1-4.2 | 25 | 9 | Φ450 | 400 | 1:630 Single bobbin take-up 2:630 Dual bobbin take-up 3:800 Single bobbin take-up 4:800 Dual bobbin take-up 5:820 Vertical pay-off 6:Or above combination |

| LWHD-450/11 | Φ8 | 1 | Φ1.7-4.2 | 28 | 11 | Φ450 | 450 | ||

| LWHD-450/13 | Φ8 | 1 | Φ1.2-φ4.2 | 30 | 13 | Φ450 | 500 | ||

| LWHD-450/9(2) | 2Xφ8 | 2 | 2Xφ2.05-3.2 | 25 | 9 | Φ450 | 900 | ||

| Linear Single Motor Drive | LHD-450/9 | Φ8 | 1 | Φ2.1-4.2 | 25 | 9 | Φ450 | 400 | |

| LHD-450/11 | Φ8 | 1 | Φ1.7-4.2 | 28 | 11 | Φ450 | 450 | ||

| LHD-450/13 | Φ8 | 1 | Φ1.2-φ4.2 | 30 | 13 | Φ450 | 500 | ||

| LHD-450/9(2) | 2Xφ8 | 2 | 2Xφ2.05-3.2 | 25 | 9 | Φ450 | 900 |

4.Layout:

5.Application Demonstration:

According to the need, it can be configured with a variety of winding forms;

Dual bobbin Automatic take-up Basket take-up Single bobbin take-up

Prev: High Speed & Low Noise Pulley Type Wire Drawing Machines

Next: Intermediate Wire Drawing Cable Machine with on Line Annealer

Our Contact

Send now