Factory Wholesale Automatic Special Shape Stone Chocolate Brushing Machine Stainless Steel Pulverizer Chocolate Crusher Machine

Description

Basic Info

| Model NO. | DR-CS |

| Application | Candy, Chocolate, Stone Chocolate... |

| Customized | Customized |

| Machine Name | Chocolate Brushing Machine |

| Capacity | 300-500kg/Hour |

| Dimension | 1200*1200*1750mm |

| Voltage | 220V |

| Weight | 360 Kg |

| Power | 4.5kw |

| Material | SS304 |

| Candy Type | Stone Chocolate... |

| Future | High Output |

| Key Selling Points | High Productivity |

| Core Components | Crushing Knife |

| Applicable Industries | Manufacturing Plant |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Video Outgoing-Inspection | Provided |

| After Warranty Service | Technical Online Service |

| Transport Package | Wooden Case |

| Specification | 1200*1200*1750mm |

| Trademark | D&R |

| Origin | China |

| HS Code | 843830000 |

| Production Capacity | 10000 Sets/Year |

Product Description

Product Parameters

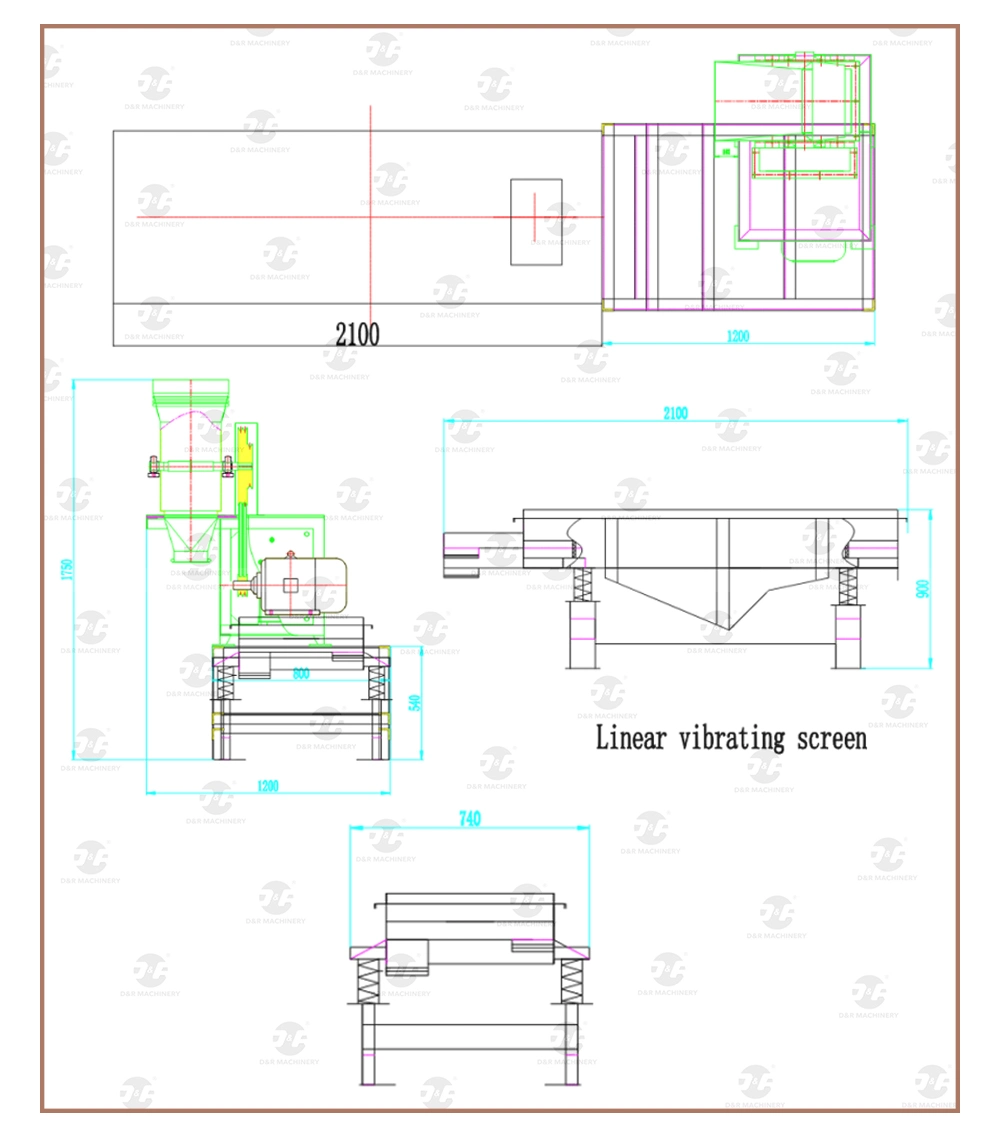

DR-CS Chocolate Brushing Machine with Classification System

| Item | Techical Parameters | |

DR-CSChocolate Brushing Machine | Power: | 220V 60Hz 3 phase 4.5KW |

Dimensions of linear vibrating screen: | 2100×740×900mm | |

Main Machine size: | 1200×1200×1750mm | |

Production capacity: | 300-500kg/h | |

Machine Frame: | Carbon steel covered SS | |

Crushing knife | Quenched carbon steel | |

Oscillating screen | Stainless Steel | |

Chocolate crusher is a kind of equipment which is specially used to break block chocolate for making stone chocolate products. Firstly, feed the block chocolate into the hopper, and then break the chocolate plate by crusher, then filter through the linear filter screen to separate the different sizes, and screen out the sizes required by customers. The unmatched particles will be recycled.

The frequency conversion of vibration motor is adjustable, the material of main frame is carbon steel, the internal crushing knife is carbon steel quenching, and the external sealing is stainless steel plate. The vibrating screen is made of stainless steel.

- Frequency conversion adjustable vibration mode

- Automatic screening system

- Production capacity: 300-500kg/h

Drawing for Reference:

Application:Company Profile

TOTAL SOLUTION ,TOTAL CARE

D&R Machinery are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards.We've built a reputation on engineering, designing and delivering high performance total-solution confectionery machinery to clients with absolute precision around the world.The confectionery machinery industry is a small world, and we've slowly become leaders in innovation and creative solutions for clients from all walks of the industry. D&R Machinery has become synonymous with one word and one world only in the confectionery machinery world and that is 'total-solution', that is end to to end turn key production of the highest quality confectionery machinery in the world.Becoming the D&R Machinery you see today starts and ends with the word 'care'. You don't become the best without a plan that ensures our clients achieve the success they desire, and at D&R Machinery it starts with care and ends with trust, reliability and innovation.

Our AdvantagesD&R Advantages

* Technical advantages, industry-leading technical team, founding team of Chinese starch mogul and young generation of highly educated bilingual engineers.* Modern service concept, provide customers with laboratory services for formula R&D, product & market analysis and planning, and control the risk before the product is put on the market.* Rich industry experience, fully communicate with customers in the pre-sales service at the initial stage of the scheme, and customize the best scheme suitable for customers in combination with rich experience in international plant construction.* For fine manufacturing, international famous brand spare parts are selected, and high-quality suppliers are selected by using the global spare parts. The purchased machined parts shall be subject to two inspections: delivery and warehousing, and shall be marked and warehoused after passing the inspection.* The whole process of nanny service, we always keeps close communication with customers in the whole project service before, during and after sales, and provides professional suggestions for relevant supporting facilities from the overall perspective of the project.

Our Service

1.D&R Machinery With Many Years Experience 2.High Technology team3.Giving The Whole Project Solution4. Consulting For Candies, Gummy, Chocolate And Its Packing5.Always Giving The Economic Machine6.Better Quality, Better Service After Sales For All Of The Customer

1

Q:Where are your company?

A:The company is located at F12, Shanshan Plaza, Yinzhou District, Ningbo, China.

2

Q:Are you direct factory?

A:We are both manufacturer and technical trading company. We are professional confectionery machine manufacturers with over 20 years in the business operating at the highest industry standards. We've built a reputation on engineering, designing and delivering high-performance total-solution confectionery machinery to clients with absolute precision around the world. Certainly,we welcome you to come visit our factory.

3

Q:What are your main products?

A:All kinds of Chocolate making machines, Candy making machines,Swiss roll and layer cake production line, Cadny bar production line and Packing machines.

4

Q:Do you have gurantee for your product?

A:We have a full quality control system.Every hardware part must be checked by the quality inspector before the products enter to the warehouse.Our electric elements are all famous brands, most of them are imported. When each machine is finished, we will invite customers to test and run the machine in our factory to ensure the high quality of our machines. Besides, we have CE, and SGS certification.

5

Q:How can we contact you?

A:Here is contact information:Contact company: Ningbo D & R Machinery

Our Contact