Graphite Mold/High Carbon Graphite Die/Upward Casting Die/ Casting Die

Description

Basic Info

| Model NO. | DT-MG-001 |

| Type | Graphite Mold |

| Composition | Carbon |

| Carbon Content | High-Carbon |

| Grade | Industrial Grade |

| Forming Way | Extruded Graphite |

| Crystal Morphology | Compact Crystalline Graphite |

| Application | Hardware |

| Function | High Temperature Resistance |

| Mold Material | Graphite Mold |

| Certification | ISO |

| Warranty | 6 Months |

| Metal Color | Non-Ferrous Metal |

| Customized | Customized |

| Condition | New |

| Material | Graphite |

| After-Sales Service | Life Time Technology Support |

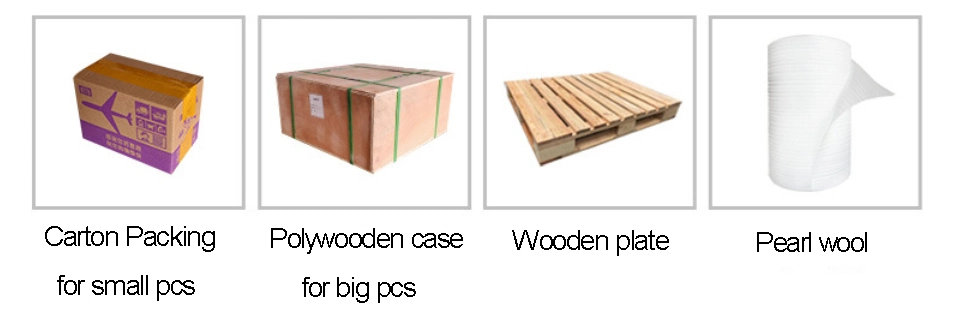

| Transport Package | Wooden Case or Carton Box |

| Specification | Customized |

| Trademark | DT INDUSTRY |

| Origin | China |

| HS Code | 84804900 |

| Production Capacity | 100tons/Year |

Product Description

Product Description

Due to graphite's special structure and features, it is widely used in industry, such as Metallurgy, Aerospace, Electrical, Scientific research, Machinery, Industry and other fields.Our graphite molds are widely used in Non-ferrous continuous casting application (Bronze, Brass, Aluminum, Copper…) and precious metals (Gold, Silver and Gems…)

GRAPHITE MOLD FOR BRASS PIPELow electric resistanceHigh temperature resistanceGood electric and thermal conductivityHigh oxidation resistanceGreater resistance to thermal and mechanical shockHigh mechanical strength and machining accuracyHomogeneous structureHard surface and good flexural strength--------WELCOME TO CUSTOMIZE------Product Parameters

| Graphite raw material brand list | ||||||||||

| Type | Brand No. | Density(g/cm) | Resistivity(μΩ·m) | Thermal conductivity(W/m) | Co-efficient of thermal expansionRoom-600ºC | Shaw type hardness(HSD) | Flexural strength(MPa) | Compressive strength(MPa) | porosity(%≤) | Ash |

| Molded graphite | DT-01 | 1.8 | 8-11 | 121.1 | 5.46 | 42 | 38 | 65 | 17 | 500 |

| DT-02 | 1.85 | 8~10 | 139.2 | 4.75 | 48 | 46 | 85 | 13 | 500 | |

| Isostatic pressed graphite | DT-03 | 1.82 | 8-11 | 119.1 | 5.5 | 48 | 42 | 75 | 15 | 50 |

| DT-04 | 1.86 | 8-12 | 142.3 | 4.85 | 52 | 48 | 95 | 13 | 50 | |

| DT-05 | 1.82 | 11-13 | 85 | 5.6 | 65 | 51 | 115 | 12 | 50 | |

| DT-06 | 1.95 | 11-13 | 89 | 5.85 | 75 | 62 | 145 | 11 | 50 | |

| Coarse particles | DT-07 | 1.6 | 9-12 | 115 | 2.7 | 25 | 13 | 22 | 1000 | |

| Fine particles | DT-08 | 1.72 | 8-11 | 120 | 2.8 | 30 | 17 | 30 | 1000 | |

Hot products

Crucible for gold/silver melting Graphite chute/seat Graphite tube diefor horizontal continuous casting for copper upward continuouscasting Multi-holes graphite mold for bar Graphite mold for oxygen free copper rod upcasting Graphite block

Our Advantages

Making graphite mold based on your drawing or your finished products' sizeInspecting, packing, uploading and shipping service;Offering all related auxiliary machines, spare parts and consumable tools;Installing and adjusting machines on site and technology training your labors for operation;Trial production on site till everything is going well;On-site technology support if customer needs.24 hours service online before sales and after sales.

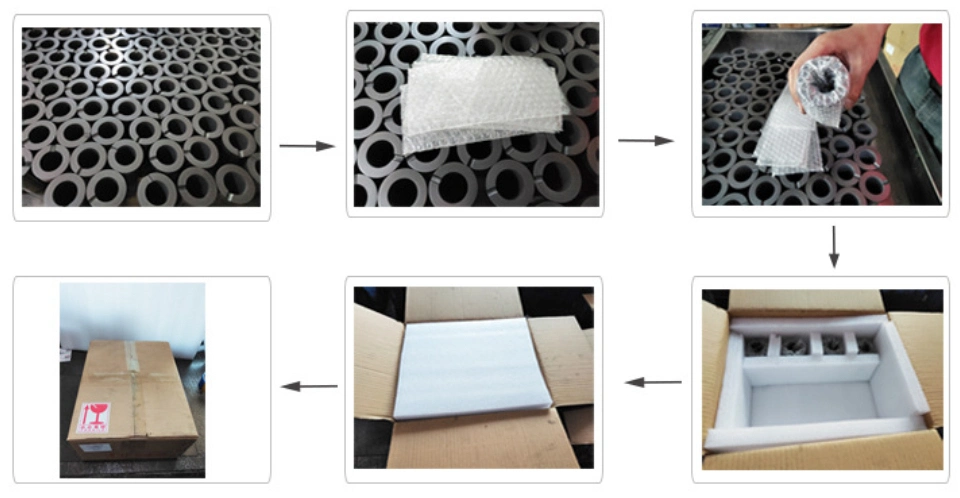

Packaging & Shipping

Company Profile

Guangzhou DT Exp. & Imp. Co. Ltd is established in 2012. We are mainly manufacturing machines for non-ferrous metal production.The main machines are electric melting furnace, holding furnace, continuous casting machine, cutting machine, peeling machine, chamfering machine, drawing machine and, straightening machine. And rolling equipment for steel and brass and copper strip.Also we are supplying Graphite products for non-ferrous continuous casting production line and tungsten steel mold for extrusion and drawing and peeling production line.We have a professional and passionate service team, including research and development department, technology support department and international after sales service department.Our advantages: Qualified Machines; Professional technology, Efficient Service, Worry-free Guarantee.Our Values: Products as the fundamental, Customers as the center, Create a win-win situation.Prev: Diamond Wire Drawing Dies/Mould Carbide Split Die in Drawing Machine

Next: OEM High Precision Standard Punch Dies Tungsten Carbide Button Die for Mold Punch

Our Contact