HDPE Pipe Extrusion Line Plastic Tube Making Machine

Overview Product Description The plastic pipe production line is widely used in the area of HDPE water supply pipes,gas

Description

Basic Info

| Model NO. | HDPE Pipe |

| Condition | New |

| After-sales Service | One Year |

| Raw Material | PVC Powder and CaCO3 |

| Motor | Simens Beide |

| Output | 180-1100kg/H |

| Temperature Control | Omron |

| Usage | Water Pipe, Electrical Pipe, Drain Pipe, Gas Pipe |

| Transport Package | PE Film Winding Wrapping |

| Trademark | Jinjia Machinery |

| Origin | Jiangsu, China |

| HS Code | 8477209000 |

Product Description

The plastic pipe production line is widely used in the area of HDPE water supply pipes,gas supply pipes,electrical pipes,etc. As well as HDPE pipe of all kinds of diameters and thicknesses. This machine group mainly consists of single screw extruder, vaccum calibrating tank, spraying cooling tank,haul-off unit,cutter, stacker. With special equipment, it can produce inner wall spiral pipe, inner wall hollow pipe, and core layer bulpo pipe. It can also produce PP, PE, ABS, PPR, PEX, silicon core pipe and other materials pipe.

Our AdvantagesADVANTAGES

1.A/C Inverter2.Reliable property3.High efficiency4.Simple operation5.PLC control Product Parameters

| Technology Parameter | ||

| Main extruder | Pipe Diameter(mm) | Max. Capacity(kg/h) |

| SJ65/32 | 20-63 | 220 |

| SJ65/33 | 20-110 | 220 |

| SJ75/33 | 50-160 | 400 |

| SJ90/33 | 90-250 | 400 |

| SJ120/33 | 160-450 | 500 |

| SJ120/33 | 400-630 | 850 |

| SJ120/33 | 500-800 | 850 |

| SJ120/33 | 315-630 | 850 |

| SJ150/33 | 500-800 | 1100 |

1.Single screw extruder

The single screw extruder is simple in design and inexpensive, so it is widely uesd. It is suitable for extrusion production of PE, PPP, PERT plastic pipes, sheets and profiles.

2.Extrusion dietu

After compaction, meleting, mixing and homogenization of PE, the subsquent material is pushed to the die by the screw. The extrusion ide is the most important part of pipe production.

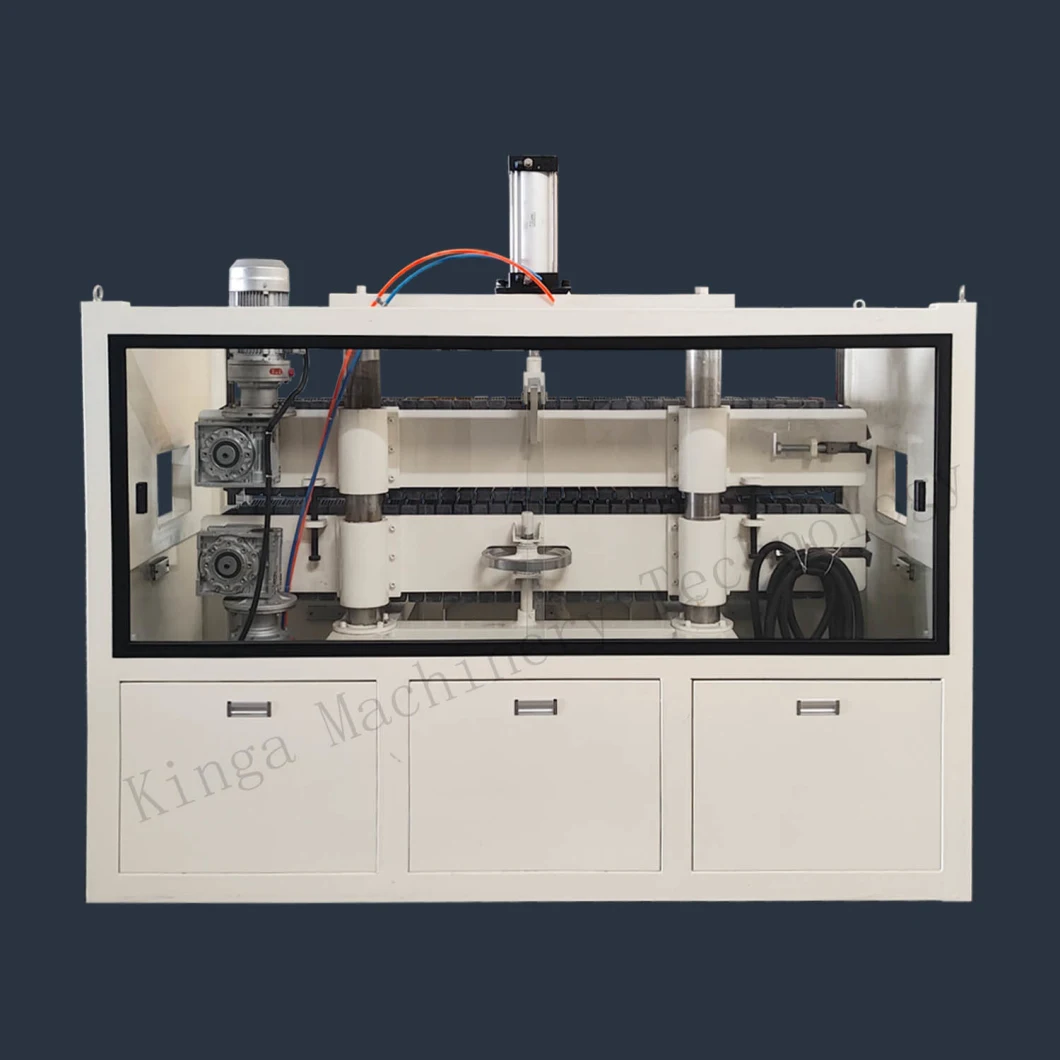

3.Vaccum calibrating tank

It is uesd for shaping and cooling pipes with a vaccum system, water circulation system, as well as front and rear moving device and left and right, height adjustment manual device, stainless steel box, circulating water spray cooling.

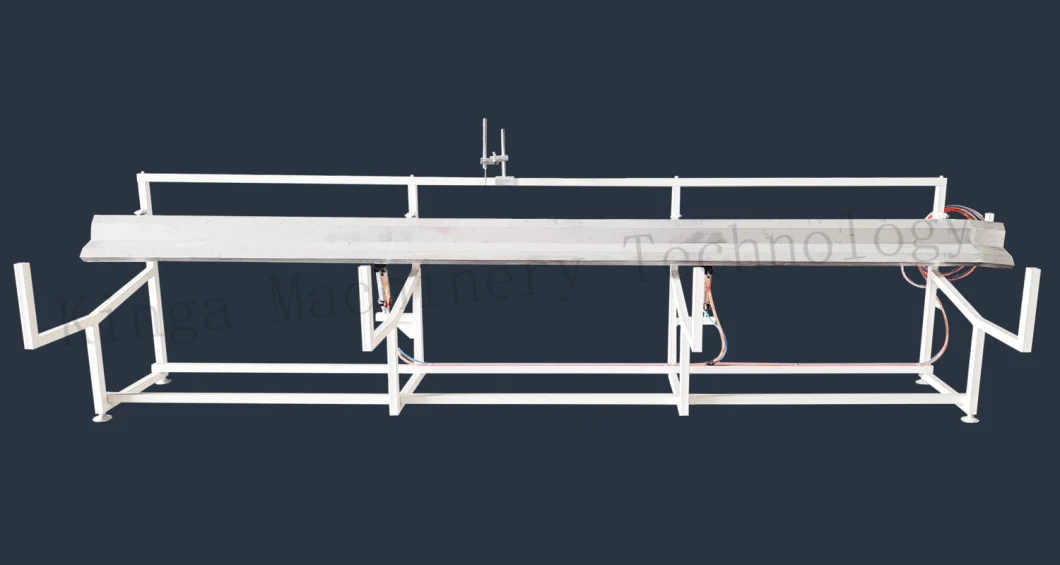

4.Spraying Cooling TankAdopting stainless steel,using auto water temperature control system to make the machine more intelligent.

5.Haul-off unit

It id uesd to continuously and autommatically lead out the cooled and hardened pipes from the machine head, and the speed is controlled by frequency conversion.

6.Cutter

After be controlled by encoder according to the required length, automiatic cutting smoothly without scraps and dust.

7.Stacker

Accept finished products and automatically turn over.Company ProfileAbout company

JINJIA is an innovative enterprise focusing on the research and development of plastic pipe and plate production technology, and providing plate, sheet, profile, pipe and recycling granulation equipments and solutions.JINJIA's core products are SPC/WPC/LVT plastic floor production line, PVC skinning foam board production line; HDPE/PVC/PP-R/PERT plastic pipe production line;PVC/WPC profile production line;waste plastic bottle chips/film recycling/cleaning/Granulation production line and various auxiliary machines,etc.With the R&D ability and well-understanding industries's experience, JINJIA can provide the customized Plastic recycling solutions to customers.

Advantages of JINJIA:

Specialized R&D team involved in Plastics Recycling Industries more than 20 years.Ability to provide the customized plastics recycling solutions;Complete sales system covering the pre-sales, sales and after sales job;Professional sales team with local language speaking ability for English, Spanish Turkish and Russian markets.The company earnestly implements CE safety standards, ISO9001 quality management system, ISO14001 environmental management system,GB/T28001 occupational health and safety system, establishes a scientific, efficient and modern management system, and takes high quality and excellent service as its core business philosophy to provide customers with stable and reliable plastic extrusion equipment keeps up with the market development and constantly introduces the old to meet the individual needs of customers.Professional R&D team involved in plastic extrusion equipment for more than 20 years;Able to provide customized plastic recycling solutions;Perfect sales system, covering pre-sale, sale, after-sales work;

Our Contact

Send now