Hyd Hydraulic Hose Pipe Press Swaging Machine for Sale

Description

Basic Info

| Model NO. | YM-P51 |

| Structure | Horizontal |

| Application | Skiving Hydraulic Hose |

| Package Size | 0.63*0.48*1.0m |

| Working Range | 6-51mm |

| Color | Blue |

| Free Dies | 11 Sets of |

| Operational Way | Button Control |

| Control | Digital |

| Power | 1.1kw - 2.2kw |

| Transport Package | Export Plywooden Case |

| Specification | 625*480*1000MM |

| Trademark | Orientflex |

| Origin | China |

| Production Capacity | 5000 Sets Per Month |

Product Description

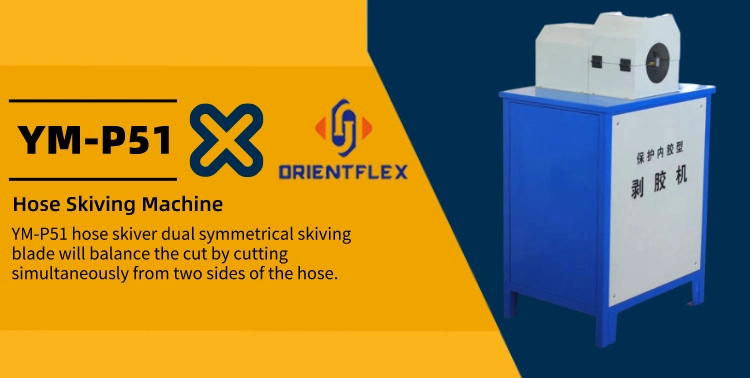

YM-P51 Hose Skiving Machine

YM-P51 hose skiver dual symmetrical skiving blade will balance the cut by cutting simultaneously from two sides of the hose. Skiving diameter adjustment for the cutting blades is made with simple motion from one knob to move both blades simultaneously, in for smaller diameter and out for larger diameter.The blade holder has marked scale for easy diameter adjustment. No tools or guess work are needed to set the skiving diameter.

| Working range | 6-51mm |

| With a knife bar | Manual |

| With the core shaft | 11 sets of |

| The special tool | The 1 part |

| Power | 1.1Kw - 2.2Kw |

| Voltage | 220V/380V |

| Size and shape | 625*480*1000MM |

| Weight | 65kg |

| Package size | 0.63*0.48*1.0 |

| Packed weight | 85kg |

Application

YM-P51 The skiving machine for the workshop. For skiving hoses up to 2" on the inside and the outside. 380V 0.75 kW drive.YM-P51variant in 1-phase or 3-phase design.YM-P51 The new skiving machine: The lowest change-over times due to preset tool. Higher productivity due to low change-over times and user friendly operation for optimum results.

Operating Procedures

1.before starting the machine, must cover the protective cover, check whether there are people and obstacles before and after the peeling machine.

2.open cover inspection must power off.

3.Before starting the machine, it is necessary to check whether the rotary knife and the die core meet the specifications of the stripping hose.

4.before starting, seriously testing rotating knife and the distance of the mold core, according to the measurement of the length of the coat, determine the work degree of rubber stripping, calculate the screw knife and rubber hose steel wire layer between the data, with similar specifications of the Angle of material under test strip first, try to peel tool setting, should from the large radial trail gradually adjusted, until clean rubber stripping, can work normally.

5.When the rubber stripping machine is in operation, if abnormal phenomenon is found, it should be stopped immediately and report the situation.

6.When the rubber stripping machine is in operation, the operator should keep the balance of the hose in his hand and not swing it up and down so as not to scratch the steel wire of the hose with the rotary knife.

7.the rotary knife must be fixed firmly, the knife shall not be too fierce, stripping work, do not remove the cutting strip by hand, so as to avoid danger.

8.No individual who has not been specially trained to do the job shall operate the machine.

9.Turn off the main power supply, clean up the work site, and keep the equipment and the ground clean and sanitary after the work is finished.

Different hose or fitting need different dies mold, like air suspension ring, air conditioning hose,brake hose,hydraulic hose,cable wire, steel pipe,steel wire rope and so on.So you can tell us what you need to crimp, then we make customize the dies mold regarding your products or requirements.

Prev: Ce Hydraulic Hose Assembly Swaging Crimping Machine for Sale Malaysia

Next: Light Rotary Equipment Hardware Lighting Processing Edge Rotary Machine Spinning Machine

Our Contact