Jinquan Supply Steel Hot Rebar Rolling Mill Production Line with ISO Quality Certificate

Description

Basic Info

| Model NO. | Rolling Mill |

| Roll Position | Vertical |

| Customized | Customized |

| Certification | SGS, ISO |

| Power Source | Electric |

| Transport Package | Nude Packaging and by Seea |

| Specification | Steel |

| Trademark | Jinquan in Chinese |

| Origin | Fuzhou, China |

| HS Code | 8455213000 |

| Production Capacity | More Than 50000 Tons of Equipments/ Year |

Product Description

Hi, welcomeWe are in Fuzhou city and and specialize in steel rolling mill machine designing & manufacturing, and have occupied in metallurgical machinery for more than 30 years. We provide Turn key project solution for our customers who demand rebar rolling mill production line, wire rod rolling mill production line, steel hot rolling section mill or strip mill production line, etc. Our company have built over 1100 steel rolling mill lines all over the world.

Jinquan Offer: The quick rolling rod production line:

The products are high precision rod of Φ10-Φ40mm and of excellent quality. Steel type:general carbon steel, high quality carbon steel, low alloy steel, and alloy steel etc., billet size is 150×150×12000mm, and the weight of the products is 2 tons. The maximum roll speed is 45m/s and the annual capacity is about 1,000,000 tons.

The main equipment of the high-speed rolling rod production line includes horizontal or vertical housing less stand mills of 650mm-350mm size, or horizontal or vertical close housing two high mill of 650-350mm size, 45°twist free heavy duty 8 stands finishing block, crop (chopping) shear, water cooling box (TMT) device, quick charging device, walking rack cooling bed, cold dividing shear, product finishing equipment, rod tying machine etc.

Common bar production line:

The products are common Bar and rod of Φ8-Φ32mm. Steel grade: General carbon steel, high quality carbon steel, low alloy steel etc., billet size is 150×150×6000mm, and the weight of the products are 1 ton. The maximum rolling speed is 16m/s and the maximum annual output is 500,000 tons with the double strand rolling.

The characteristic of this line is double strand rolling. The main equipment of these are horizontal two high openable housing mill of 550-350 size (or using three high mill stand for break- down). pusher, discharger, disk type crop flying shear, disk type dividing flying shear, water cooling box, walking rack cooling bed with running slots, cold dividing shear, finishing equipment, tying & collection machine etc.

Company profile

| Company name | Fujian Jinquan Group, the Group consists of Fuzhou Jinquan Metallurgical Machinery, Fujian Tianfeng Machinery And Fuzhou Zhongfu Water Meter |

| Histrory | More than 30 years development in the business of metallurgical industry of steel rolling mills, we have built around 1100 steel rolling mill production lines around the world. |

| Basic information | The group has more than 1000 employees, numbers of professinonal and technical personnel are near to hundred, covers an area of total of nearly 96000 cubic meters, |

| Main product(manufacturer) | We mainly produce steel rolling mills, and Turn Key project service, offering whole package service from designing, manufacturing, installation, commissioning, of course after-sale service, to our customers of steel bar rolling mills production mill, wire rod production line, section steel hot rolling production lines(its finshed products are like angle steel, channel steel, square steel etc...) and steel strip production line and their electric control equipment, also CCM (continuous casting machine) etc... |

| To our potential customers | Dear, if you plan to enter into steel rolling mill business, or you need the rolling mill equipments for products like steel rebar, bar, wire rod, steel flap, steel channel, steel H beam, etc, and you are welcomed to share your questions or problems about metallurgical industry, we are at your service at any time. |

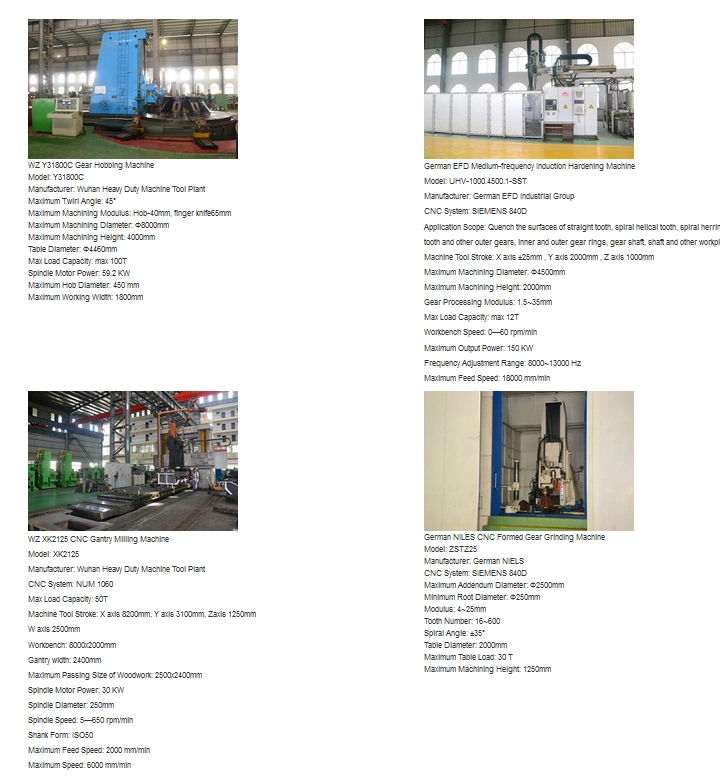

CertificateTechnical equipment

Our advantages

1: Rich experience: The Jinquan Group since the start-up in 90's, it has been tightly involved in the iron and steel industry, we have built 1100 steel rolling mill lines all over the world. 2: Technology and Equipment owned: Numbers of professinonal and technical personnel are near to hundred, he has more than 600 small and medium-sized advanced equipments to produce rolling mill machines and provide customers with rolling mill machines. 3: Staff principle: Customers first. And we will do our best to provide you with good service, and stand in customers's shoes to think questions.

Custom-designed according to the special needs of mature production line:

According to the needs of users, to provide technical solutions and other services security: Offer single piece of rolling mill machines and also whole package service from designing -manufacturing -installing-commissioning for production line, like wire rod mill, bar mill, section steel mill(like, angel steel, square steel, flap steel, I beam, H beam, etc...) and strip steel mill. 1: Total plan layout and detailed process equipment layout, production technology; 2: Our engineers is at your service at any time. 2: On-site equipment installation, instruction. 3: The production line commissioning technology guidance. 4: Required staff technical training; 5: After-sales service will be guaranteed. 6: Quality warranty will be guaranteed. 7: Other detailed services, like water system equipments, compressed air system equipments, firefighting system, etc., will be showed on quotation.

Service Assurance

The Jinquan Group the face of hundreds of users around the world have established efficient and professional service system. According to the customers' needs and the actual situation to tailor the optimal solutions and provide the best quality equipment products, bear the guidance of a full set of production line equipment of metallurgical machinery installation, commissioning, maintain production, and implementation of the tracking service guarantee spare parts supply, provide timely and efficient service to customers around the world.

Pre-sale: (1) customers with Division I professional to communicate and understand the needs of customers. (2) technical staff to the the user site planning venue to provide the best solution. (3) the optimal design of the hardware based on customer demand;

Sales: (1) to provide the best quality products, the two sides of the acceptance of the product; (2) to provide customers with a list of spare parts; (3) to help customers develop the best on-site construction program.

Aftermarket: (1) The to assign professional engineering staff, arrived at the scene to guide the installation and commissioning; (2) Long-term real-time tracking of user field devices use to provide timely and effective life-long service to the user.

We have always been committed to providing customers with the best quality service, we will strive to provide better service for customers.

Thanks for your watching.

Prev: Steel Rolling Mill Machine (turn-key) Hot Rolling Mill Process for Rebar Wire Strip Production Line

Next: Prestressed/Post Tensioning Round Cold Rolling Pipe Making Machine for Cement Grouting

Our Contact