Basic Info

| Model NO. | Plastic Pipe Productuion Line |

| Condition | New |

| Product Name | Plastic Pipe Extrusion Production Line |

| Keywords | PP Pprt PE Pert Pipe Extrusion Line |

| Pipe Diameter Range | 200mm |

| The Types of Pipes That Can Be Produced | PE /PPR /Pprt Pipe |

| Main Accessories 1 | Stainless Steel Vacuum Calibrator |

| Main Accessories 2 | Vacuum Calibration Box |

| Main Accessories 3 | Tractor |

| Main Accessories 4 | Cutting Machine |

| Main Accessories 5 | Stirrer |

| Main Accessories 6 | Automatic Winder |

| Screw Design | Single Screw Extruder |

| Suitable for | Extrusion Production of PE, PPR, Pert Plastic Pipe |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | MEETYOU MACHINERY |

| Origin | Jiangsu, China |

| Production Capacity | 500 Set / Month |

Product Description

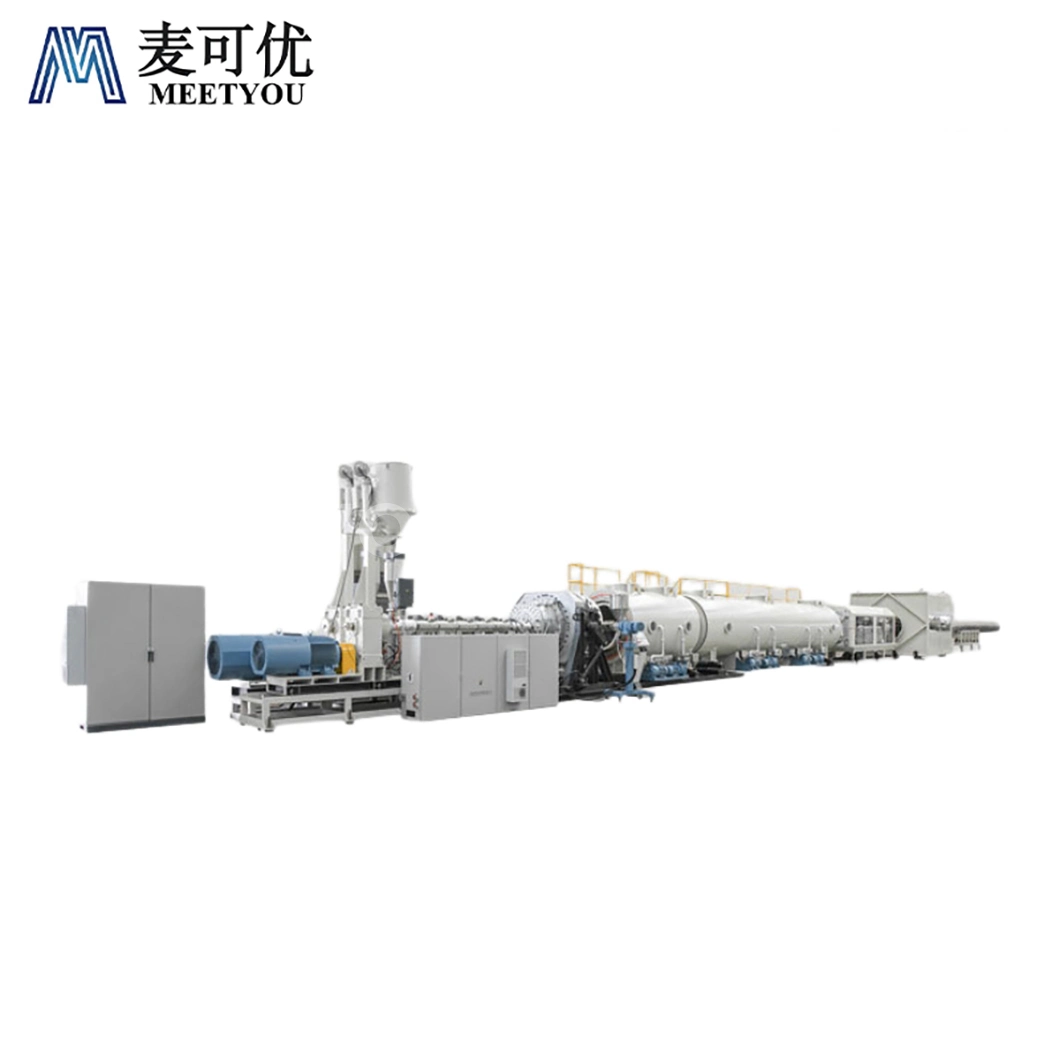

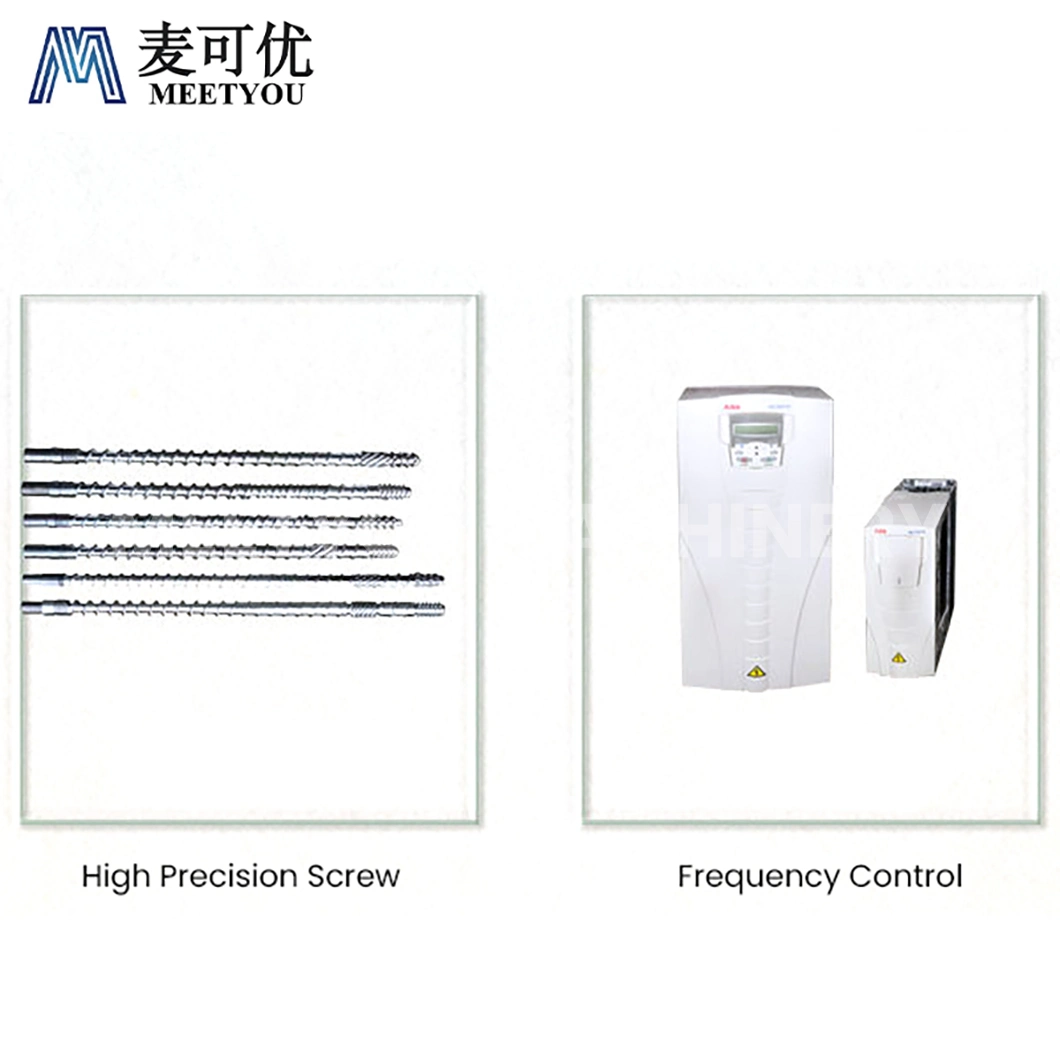

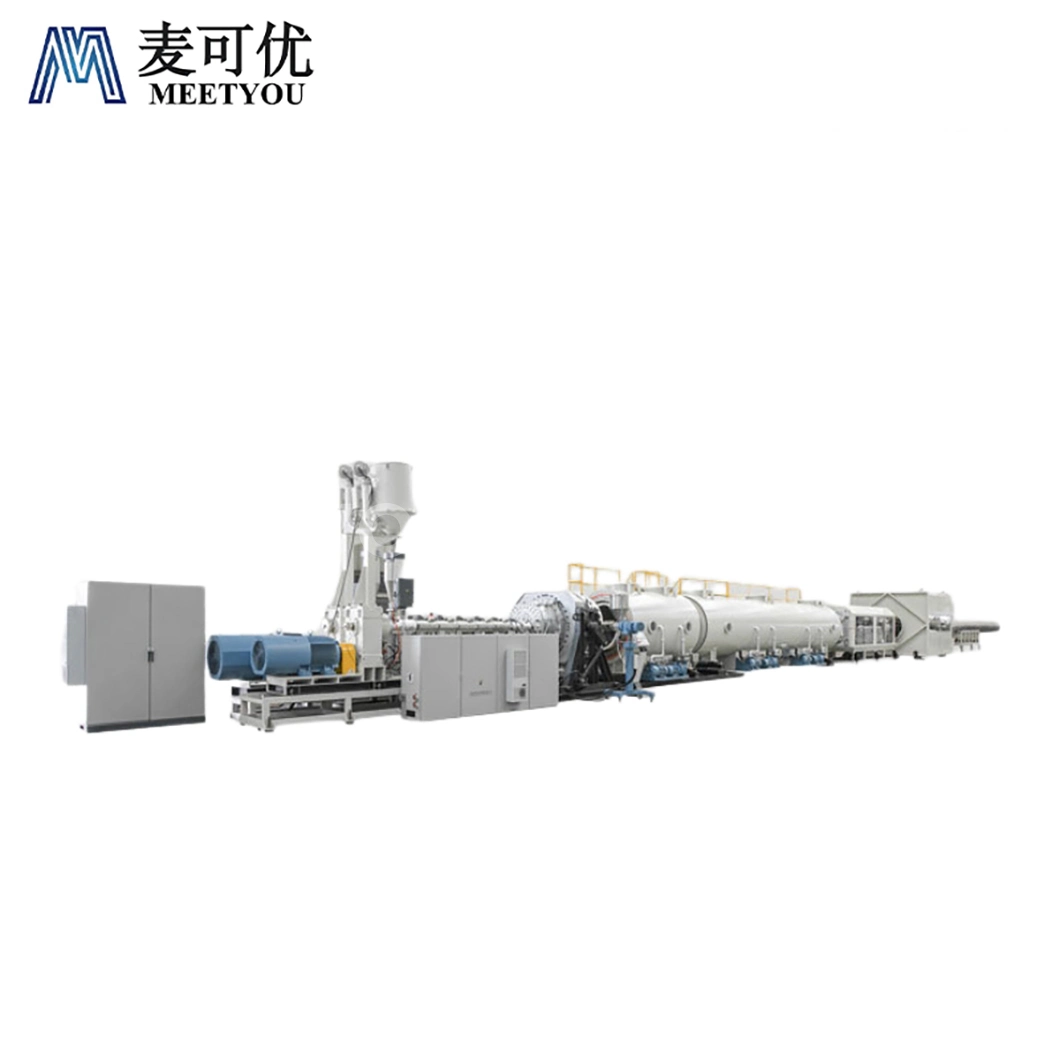

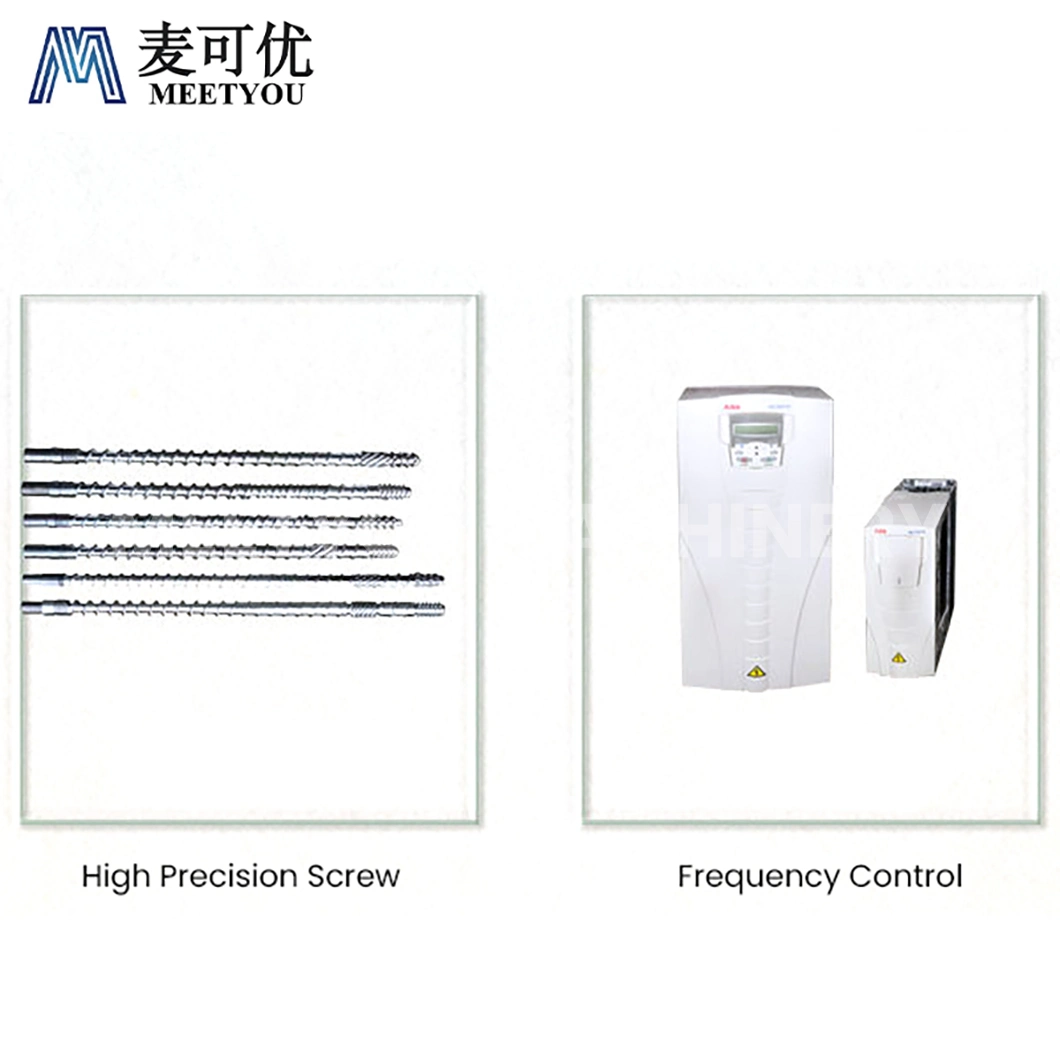

MEETYOU MACHINERY China Fully Automatic Pipe Making Machine Line Supplier Wholesale 16-63mm Plastic Pipe Extrusion Production Line Custom Tube Production Line Product DescriptionPE pipe production lineIt is composed of vacuum sizing box, tractor, cutting machine, turning rack and so on. Chipless cutting, saw blade cutting or planetary cutting can be selected, the unit has reliable performance and high production efficiency.- Customized processing according to customer requirements- Composite production needs, high degree of specialization- One year warranty, lifetime service- High precision screw design- Frequency conversion control system design

Product Parameters

SINGLE SCREW EXTRUDERSingle-screw extruders are simple in design and cheap, so they are widely used. It is suitable for the extrusion production of PE, PPR, PERT plastic pipes, plates and profiles.EXTRUSION DIEAfter compaction, melting, mixing and homogenization of PE, the subsequent materials are pushed to the die head through the screw,Extrusion die is the key building part of pipe forming.VACUUM CALIBRATION TANKFor shaping and cooling of pipes, the vacuum setting water tank is equipped with a vacuum system for shaping and coolingAnd water circulation system, stainless steel box, circulating water spray cooling, vacuum setting water tank is equipped with frontRear moving device and left and right, height adjustment manual device.SPRAY COOLING BOXIt is mainly composed of a sink, a rack, an up and down lifting mechanism, and a stainless steel water tank.The cooling water is atomized and sprayed from the special nozzle through the water pump, so that the product can be obtainedTo 360 degrees all-round cooling.TRACTORIt is used to continuously and automatically lead the cooled and hardened pipes out of the machine head, and the speed is adjusted by frequency conversion.CUTTING MACHINEAfter being controlled by the travel switch according to the required length, it will automatically cut and turn over with a delay.Implement flow production and cutting process is completed by electric and pneumatic drive, the cutting machine is equipped with dust suctionThe device can suck out the cutting debris in time and recover them.TURNOVER RACK (optional upon request)Accept finished products and turn over automaticallyAUTOMATIC WINDING MACHINE(optional upon request)This machine is equipped with two alternate winding discs to ensure the continuity of production, suitable for plastic winding packaging,Self-winding. Pneumatically open or close the baffle, and equipped with a polished rod cable puller,Automatic wiring, easy to operate.

Detailed Photos

FAQQ: Is your company factory or trade company?

A: we are factory, we are engaged in this business for 11 yearsQ: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers

Q: What is the payment term?

A: The best way for both of us is 30% T/T deposit and 70% T/T balance payment before shipping, since we will test the machine before shipping. Of course, you can choose the way that more convenient (Payment terms: T/T, L/C, Western Union etc.)Q: How about after service?

A:We can offer 12 months free warranty since the machinery arrived at your factory. We also offer space parts or repair service to our customer anytime and anywhere, we will send our technician to your factory if necessary

Q: How to reach our factory?

A: It will take 40 minutes from Shanghai International Airport to our factory by car, and we will arrange our driver to pick you to our factory anytime.