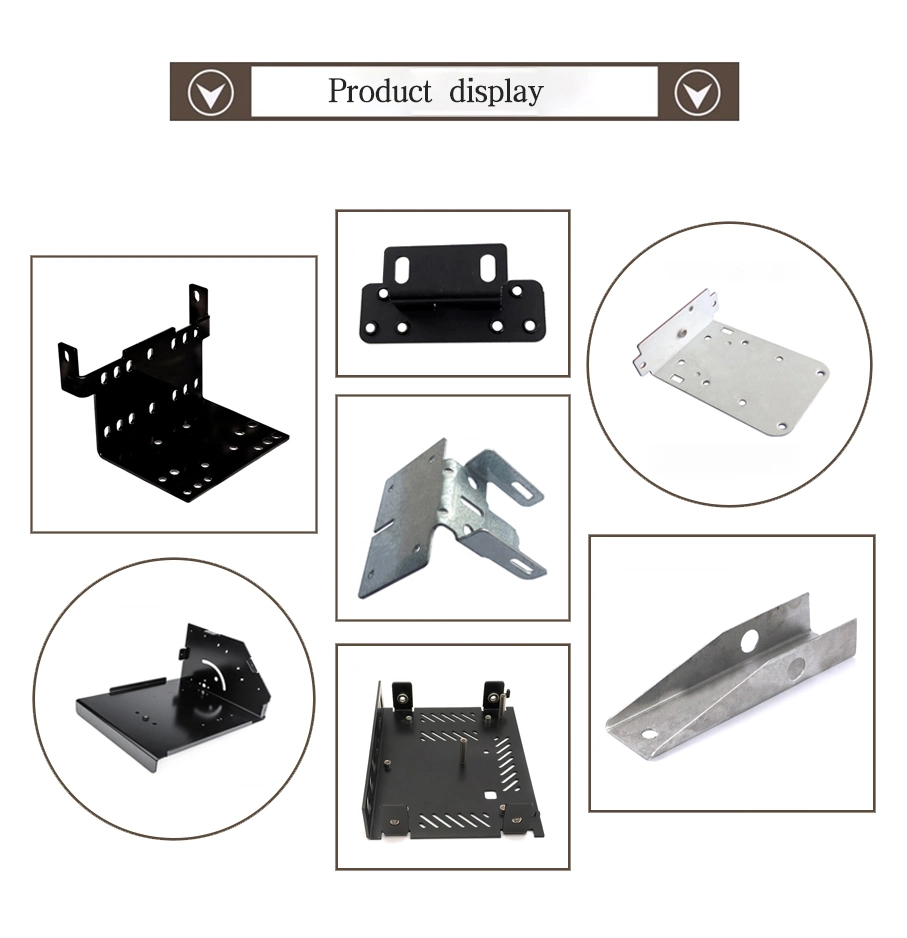

Metal Satmping Sheet Metal Fabrication Parts for Auto Engine

Description

Basic Info

| Model NO. | As customer request |

| After-sales Service | as Per Specification |

| Warranty | 6 Months |

| Type | Cold Stamping |

| Processing Type | Shaping Metal |

| Material | Stainless Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Open |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.2mm |

| Customized | Customized |

| Material Type | Aluminum/Brass/Stainless Steel/Cooper Sheet |

| Name | Sheet Metal Stamping Parts |

| Place of Origin | Shandong, China |

| Technics | Stamping, Punching, Grinding |

| Quality Stardard | DIN/JIS/BS/ASTM/CE |

| R & D Service | Design and Drawing |

| Dimension | Customized |

| Unique | 15 Years of Manufacturing |

| Technology | Stamping |

| OEM and ODM | 100% with Drawings and Samples |

| Delivery Time | 30 Days After Payment |

| OEM Sample | About 10 Days |

| MOQ | 100 Pieces for Trial Order |

| OEM Package | Anti-Rust Package System |

| Inner Package | Carton Box/Plastic Bag |

| Transport Package | Plywood Box |

| Specification | CE, SGS |

| Trademark | ShengAo |

| Origin | Weifang, Shangdong, China |

| HS Code | 8431390000 |

| Production Capacity | 50000PCS/Month |

Product Description

Metal Satmping Sheet Metal Fabrication Parts for Auto Engine1.Small details make big difference. We promise:All the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit . 2. The craftsmanship of all parts we machined is controlled rigorously, Every product has its own process card and process chart.3. Our quality inspection procedure is quite strict.it must self-inspected during production, we have flow inspectors and professional inspectors. 4. Each size of product must be tested one by one after completing production and provide quality report.5. The most important point, we are the entity factory, not trading company. Price is the composition of the actual product quality price. Quality can guarantee more controllable higher than trading company. The price is competitive, at least reducing the trade company's service fee.6.We have many years of export experience,exports to the US,Europe, Japan and other countries and regions. 7.Our team are more professional. We have more reasonable price and better quality controlling than trade company. And our language ability is also diversified.

Our manufacturing capability: ·Punch range from 16T to 500T ·Hydraulic plate shears ·Bending machine ·Hydraulic draw-bench ·Blanking, piercing, bending, forming, and deep drawn

| Material | Aluminum 6061, 6063, Stainless Steel, Iron, brass |

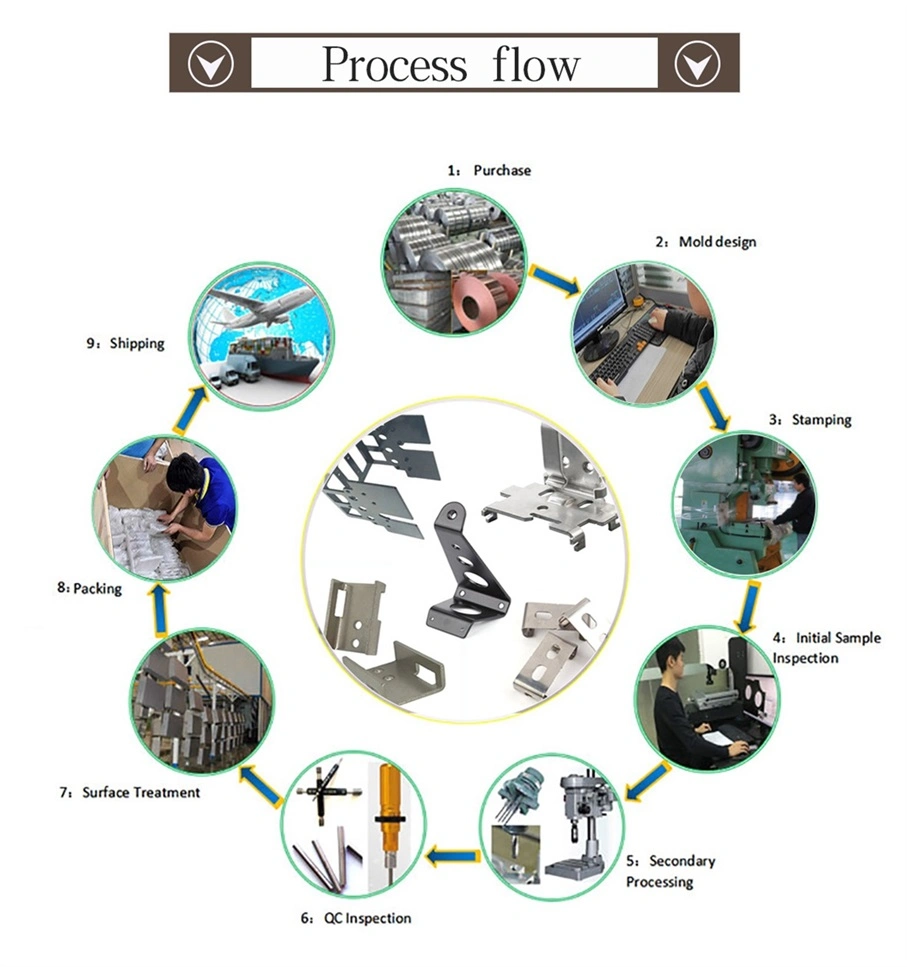

| Processing Craft | Drawings→ mould making → stamping →rough machining → CNC machining (if need) →surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. 2.Third Party inspection available upon requirement. |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Quality Guarantee | 3 years |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance, smooth surface roughness is Ra3.2 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. |

1. ISO9001-2015.

2. Has advanced euipment and over 15 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Process: Precision made. Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

| Material | Carbon steel, stainless steel, brass, zinc/aluminum alloy etc |

| Surface treatment | Galvanized, zinc plating, powder coating, electroplate. |

| Application | Construction parts, furniture hardware, electronic hardware, machinery parts, art-ware |

| Tooling room | Yes, mold was made by ourselves. |

| Machinery capability | Hydraulic press machine, cold chamber machine, machining center, the machines for bending, grinding, milling, drilling, welding, polishing, shot blasting machine. |

| Packing | Film/Carton/Plywood box, or according to customer's requirement. |

| OEM/ODM | Acceptable |

Q: Why choose Shengao product? A: We shengao have our own plant Weifang Shengao machinery , therefore, we can surely promise the quality of every product and provide you comparable price. Q: Do you provide OEM Service? A: Yes, we provide OEM Service. Q: Do you provide customized Sheet Metal Stamping/Stamped Parts/Punching Parts? A: Yes. Customers give us drawings and specifications, and we will manufacture accordingly. Q: What is your payment term? A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there is anything we can help you, welcome to contact us anytime!

Our Contact