OEM Stainless Steel Stamping Tractor Parts of Deep Drawing

Description

Basic Info

| Model NO. | WF-JF |

| Surface Processing | Polishing |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | General Stamping |

| Tolerances | 0.02mm |

| Customized | Customized |

| Material Type | Aluminum/Brass/Stainless Steel/Cooper Sheet |

| Name | Sheet Metal Stamping Parts for Machine Housing |

| Place of Origin | Shandong, China |

| Technics | Stamping, Punching, Grinding |

| Quality Stardard | DIN/JIS/BS/ASTM/CE |

| R & D Service | Design and Drawing |

| Dimension | Customized |

| Unique | 15 Years of Manufacturing |

| Technology | Casting + Machining |

| OEM and ODM | 100% with Drawings and Samples |

| Delivery Time | 30 Days After Payment |

| OEM Sample | About 10 Days |

| MOQ | 2000 Pieces for Trial Order |

| OEM Package | Anti-Rust Package System |

| Inner Package | Carton Box/Plastic Bag |

| Transport Package | Pallet, Iron Frame, Flywood Box. |

| Specification | As your requirement |

| Trademark | Shengao |

| Origin | Weifang City, Shandong Province |

| HS Code | 8483500000 |

| Production Capacity | 50000PCS/Month |

Product Description

OEM Stainless Steel Stamping Tractor Parts of Deep DrawingProduct Type | Stamping | |||

Materials | Coppor, Brass, Stainless steel, galvanized sheeet, steel sheet, aluminum sheet, tinplate, spring steels | |||

Surface Finish | Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel Plating, Chrome Plating, Zinc Plating,Gold Plating,Silver Plating,Dacromet, Enamel Coating,electrolysis, Black finish, Wiredrawing etc. | |||

Process Methods | Stamping, Bending, Deep Drawing, Welding | |||

Application | All kinds of cars,machinery,home appliance,electronic products,electric appliance,stationery,computers,power switches,miniature switcher,architecture,commodity and A/V equipment,hardware and plastic molds,sports equipment and gifts,and more. | |||

Drawing Format | CAD,3D(stp,igs,dfx),PDF | |||

Certificate | ISO 9001:2015,SGS | |||

MOQ | according to your requirement | |||

Tolerance | In general:±0.1mm, according to the product structure and your requirement | |||

Delivery time | For mould about 25-40 working days. For product about 15-30 working days,according to thedrawing and quantity. | |||

One-stop Service | Custom Design, Fabrication, Assembly And Delivery | |||

Mould Material | CR12 ,CR12MOV, SKD11,D2,DC53 | |||

Mould Life Time | 500000-1000000pieces | |||

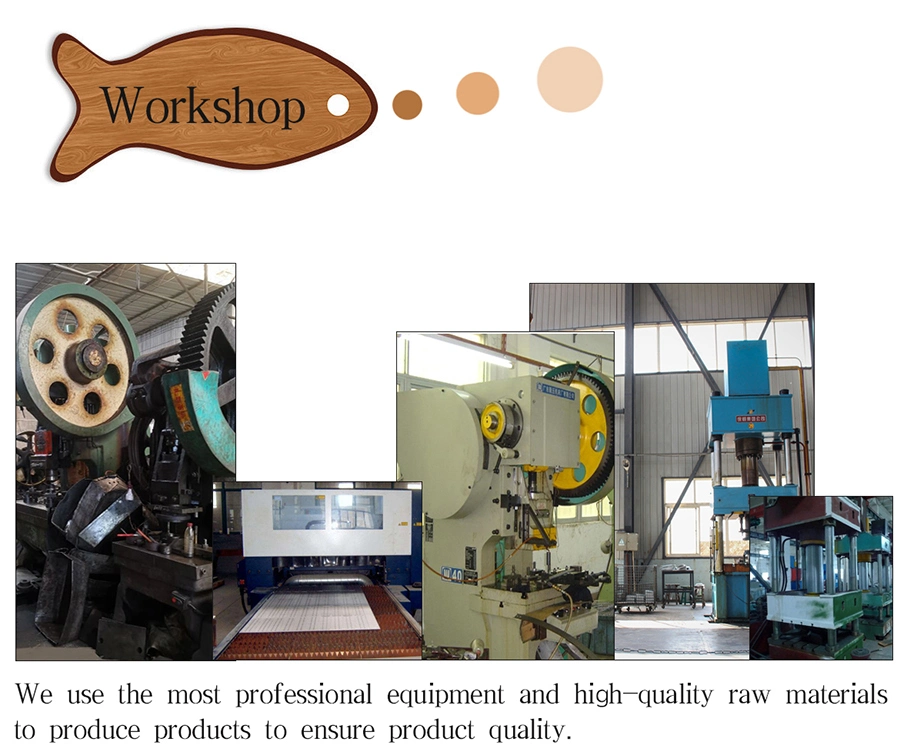

Our manufacturing capability: ·Punch range from 16T to 500T ·Hydraulic plate shears ·Bending machine ·Hydraulic draw-bench ·Blanking, piercing, bending, forming, and deep drawnQuality control:*We have specialized QC testers to check the quality of the products according to different customers' requirements. Usually, it's random inspection, and we also offer 100% inspection at a reasonable price if required.*We have IQC to check the dimensions and surface of the incoming material*We have PQC to inspect full-course during the manufacturing processing*We have FQC to inspect all the anodizing/plating and other finishes' products from our supplier and proceed with the professional quality and appearance inspection before shipping.

1. ISO9001-2008.

2. Has advanced euipment and over 15 years experience.

3. Price: Competetive price, Precision made. Experience & Reasonable QC that you can reply on.

4. Process: Precision made. Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.

| Material | Carbon steel, stainless steel, brass, zinc/aluminum alloy etc |

| Surface treatment | Galvanized, zinc plating, powder coating, electroplate. |

| Application | Construction parts, furniture hardware, electronic hardware, machinery parts, art-ware |

| Tooling room | Yes, mold was made by ourselves. |

| Machinery capability | Hydraulic press machine, cold chamber machine, machining center, the machines for bending, grinding, milling, drilling, welding, polishing, shot blasting machine. |

| Packing | Film/Carton/Plywood box, or according to customer's requirement. |

| OEM/ODM | Acceptable |

Q: Why choose Shengao product? A: We shengao have our own plant Weifang Shengao machinery , therefore, we can surely promise the quality of every product and provide you comparable price. Q: Do you provide OEM Service? A: Yes, we provide OEM Service. Q: Do you provide customized Sheet Metal Stamping/Stamped Parts/Punching Parts? A: Yes. Customers give us drawings and specifications, and we will manufact accordingly. Q: What is your payment term? A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there is anything we can help you, welcome to contact us anytime!

Our Contact