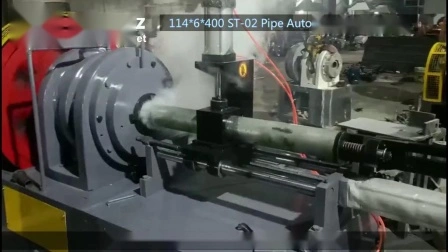

Pipe Auto Swaging Machine for Ground Screw

Pipe Shrinking Machine for Ground Screw Piles Feature: With Pneumatic or Hydraulic feeding, low noise, easy operation, h

Description

Basic Info

| Model NO. | ST-01 02 03 |

| Type | Hydraulic Machine |

| Forging Forming Method | Mold Forging |

| Power Source | Hydraulic Pressure |

| Feature | Automation |

| Warranty | 12 Months |

| Customized | Non-Customized |

| Advantage | Simple Structure |

| Condition | New |

| Transport Package | Export Packing |

| Specification | max pipe 140mm dia, 6mm thickness, 400mm tapered L |

| Trademark | SOMEBIZ |

| Origin | China |

| HS Code | 8462919000 |

| Production Capacity | 20 Sets Per Month |

Product Description

Pipe Shrinking Machine for Ground Screw PilesFeature:

With Pneumatic or Hydraulic feeding, low noise, easy operation, high output and stable performance.

The forming time is short, the efficiency is high, the processing surface is smooth, and the workpiece has no scratches.

The machine mold is easy to change, and metal pipes of different shapes can be processed with the corresponding molds to meet different needs.

Application:

Applicable to the taper forming process for automobiles, furniture, lighting, bicycles, grouting small catheters etc.

Working principle:

The end of the steel pipe is superposed to be heated by Electromagnetic Induction Furnace, when a certain temperature is reached, steel pipe end insert into the tapering machine, pipe end is hit by the forming mold while mechanical transmission the pipe, until it reaches the required shape.

Main technical parameters

Working voltage main line 380 V 50HZ

Oil pump motor power AB-25 0.9KW 1420R/M

| Model | Description | Pipe Max Diameter | Max Thickness | Max Tpaered Length | Mold Length | Spindle speed Rpm | Power Kw | Machine Size | Machine Weight | |

| 76*4* 340 | With Pneumatic cylinder | 76 | 4 | 340 | 360 | 248 | 11 | 2.9*1.7*1.5 | 2.5 | |

| 114*6*380 | With Pneumatic cylinder | 114 | 6 | 400 | 400 | 248 | 15 | 3*1.8*1.7 | 3 | |

| 140*6*430 | With Hydraulic cylinder | 140 | 6 | 400 | 450 | 248 | 18 | 3.5*1.8*1.7 | 5 | |

Construction:

| Item | Name | Spec. | Qty | Brand |

| 1 | Motor | 1 | Bao ding hao ye | |

| 2 | Contactor | 2 | Chint | |

| 3 | Time Relay | 3 | Delixi | |

| 4 | Relay | 2 | XIN MEI | |

| 5 | Heat protector | 3 | XIN MEI | |

| 6 | Switch button | 6 | Delixi | |

| 7 | Cabinet | 2 | ||

| 8 | Foot switch | 1 | Delixi | |

| 9 | Electromagnetic valve | 2 | D&C | |

| 9 | Clamping cylinder | 125*200 | 1 | ZGXCL |

| 10 | Feeding cylinder | 125*600 | 1 | ZGXCL |

| 11 | Water separator | 1 | AIRTAG | |

| 13 | Water pump | 125v | 1 | JINQUAN |

Operation Manual

- Place the machine on a flat ground with reliable grounding.

- Add engine oil No. 40 about 20kgs, to the level meter. Automatic cycle of the whole machine, no need add oil special for mould.

- Check the circuit in the electronic control cabinet firstly, Connect the mainframe power line (380V three live wire, one neutral wire).

- Connect Air Hose, adjust pressure 5 or 6 Mpa.

- Start Machine, Start Oil pump. Auto Operate the machine:

Automatic mode operation:

Machine Start-Oil pump Start -step switch, Cylinder start clamping- automatically push forward - automatically return to stop - take out the pipe.

Time distribution box has time relay to adjust.

Connect Air Hose, adjust pressure 5 or 6MpaMould installation and adjusting

- Open the taper die door cover

- The four pipe shrinkage moulds made in advance are respectively installed in the pipe shrinking machine.

- Turn the pulley to the top of the die to see if the four dies are round.

- Carefully complete the above steps, check all the mold installation, so you can test the machine.

High Frequency Furnace for Ground Screw Pipe Heating

Advantages: quick heating, convenient installation, small size, light weight and convenient use;

Fast start, less power consumption, good effect, fast heating, less oxide, no waste after annealing;

Adjustable power, adjustable speed.

Main technical parameters:

Input power: 90Kw, 120Kw, 160Kw. Input voltage: 380V 50-60HZ.

We recommend 90Kw furnace to match tapring machine ST-02 76*4*340,

120Kw Furnace to match Tapering Machine ST-03 114*6*400,

160Kw Furnace to match Tapering Machine ST-04 140*6*400.

Prev: China Factory Price Hydraulic Steel Wire Swaging Machine

Next: Automatic Single Head Hydraulic Pipe/Tube Swaging Machine

Our Contact

Send now