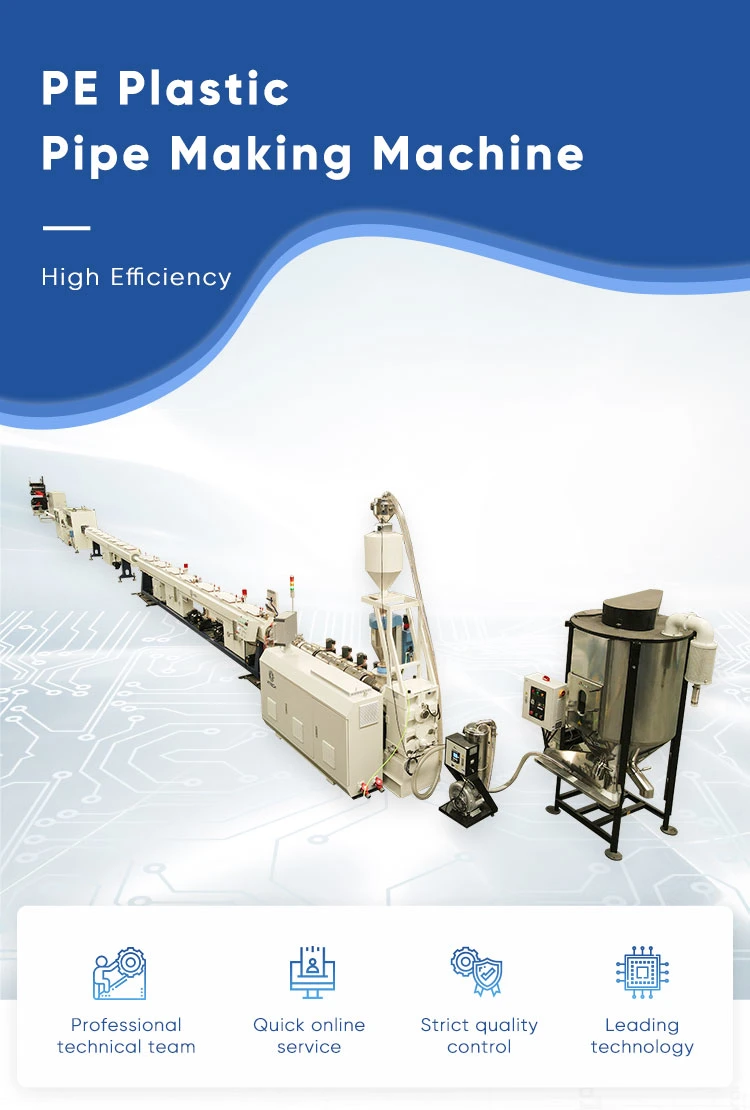

Plastic PVC/PE/PP/PPR Single Wall Corrugated/Corrugation Electrical Conduit Protective Sheath Pipe Tube/Hose Extrusion Production Line

Application:PE Plastic Pipe Extrusion Line is mainly used in the production of agricultural drainage, water supply and c

Description

Basic Info

| Model NO. | ASS |

| Warranty | 1 Year |

| Product Type | PE Water-supply Pipes |

| Screw No. | Double-screw |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| After-sales Service | Provide |

| Controller | Siemens PLC |

| Output Pipe Size | 200~1600mm |

| Motor Brand | Siemens, Weg, Sew |

| Gearbox | Vertical Type Sew/Falk Brand |

| Inverter | ABB/Schneider/Siemens |

| Bearing | SKF, NSK |

| Barrel & Screw Material | Bimetallic Barrel & Screw |

| Output Capacity | 200-700kg/H |

| Raw Material | HDPE Resin |

| Transport Package | Wooden Pallets |

| Specification | ASS |

| Trademark | KITECH |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 10-30 Sets/ Year |

Product Description

Application:PE Plastic Pipe Extrusion Line is mainly used in the production of agricultural drainage, water supply and cable conduit purposes. The unit consists of single extruder machine, mold, vacuum forming tank, multi-claw haul-off machine, planetary(chipless/non-dust cutter) cutting machine, stacker and so on. And the line can be equipped with Comptroller thickening instrument or computer ink-jet printer, etc. to achieve the production and manufacture of high-grade tubing.Great advantages:

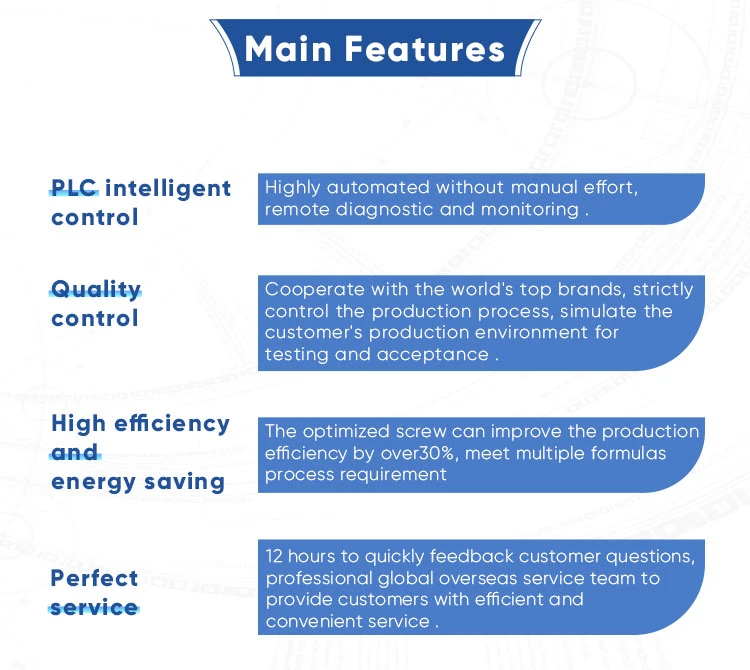

1. High lineal extrusion speed, big capacity and low power consumption, and achieved multi-layers co-extrusion with 1-5 layers.2. The copper bush is more wear-resisting and prevent material leakage which can guarantee a stable running of extruder.3. Material feed via spiral groove, efficient transmission and can effectively reduce back-pressure on extruder.4. Unique design (barrier, shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and stable output capacity.5. High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation;6. PCA(pipe air cooling system) of die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe surface;7. Intelligent PLC controlling system with human-friendly interface make the operation easily and conveniently;8. Chip-free cutter ensuing flat and smooth cutting surface of pipe.

Pipe Machine capacity and relevant parameters of the Pipe machines :

| Diameter range(mm) | Extruder model | Max.Capacity(kg/h) | Max.lineal speed(m/min.) | Extrusion power(KW) |

| 20-63 | ASS65/33 | 220 | 12 | 55 |

| 20-63 | ASE60/38 | 460 | 30 | 110 |

| 20-63Dual | ASE60/38 | 460 | 15*2 | 110 |

| 20-110 | ASS65/38 | 220 | 12 | 55 |

| 20-110 | ASE60/38 | 460 | 30 | 110 |

| 20-160 | ASE60/38 | 460 | 15 | 110 |

| 50-250 | ASE75/38 | 600 | 12 | 160 |

| 110-450 | ASE90/38 | 850 | 8 | 250 |

| 250-630 | ASE90/38 | 1050 | 4 | 280 |

| 500-800 | ASE120/38 | 1300 | 2 | 355 |

| 710-1200 | ASE75/38 ASE90/38 | 1450 | 1 | 160 250 |

| 710-1200 | ASE90/38 ASE90/38 | 1900 | 0.6 | 280 280 |

Prev: Hot Sale High Quality Steel Pipe Production Line Cold Rolling Mill in China

Next: Mattress Comprehensive Rolling Durability Tester of Furniture Testing Machine

Our Contact

Send now