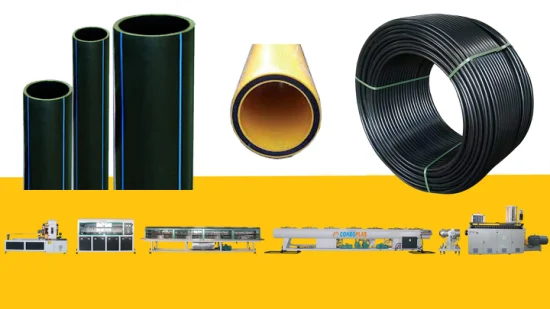

Plastic Single Screw Extruder Double Three Triple ABA Layer PPR PE HDPE LLDPE LDPE Irrigation Water Supply Energy Gas Hose Pipe Tube Extrusion Production Line

Description

Basic Info

| Model NO. | GF315 |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Customized |

| Condition | New |

| After-sales Service | One Year for Free |

| Electrical Components | Siemens, ABB, Omron, FUJI, etc. |

| Delivery Time | Around 40 Days |

| Pipe Diameter | From 16mm-1200mm |

| Motor Brand | Siemens |

| Extruder Control | by Siemens PLC Screen Touch |

| Motor Drive/Inverter | ABB Brand |

| Pipe Usage | Water, Engergy, Gas, Irrigation, etc. |

| Production Speed | Around 0.5-20meter/Minute |

| Shipment | LCL and FCL |

| Machine Installation | Available |

| Transport Package | Plastic Film and Wooden Box |

| Specification | Pipe size upto 1200mm |

| Trademark | CONBOPLAS |

| Origin | Zhangjiagang |

| HS Code | 84778000 |

| Production Capacity | 30 Sets Per Month |

Packaging & Delivery

Package size per unit product 1000.00cm * 1000.00cm * 1000.00cm Gross weight per unit product 5000.000kgProduct Description

Plastic Single Screw Extruder Double Three Triple ABA Layer PPR PE HDPE LLDPE LDPE Irrigation Water Supply Energy Gas Hose Pipe Tube Extrusion Production LineProduct Description

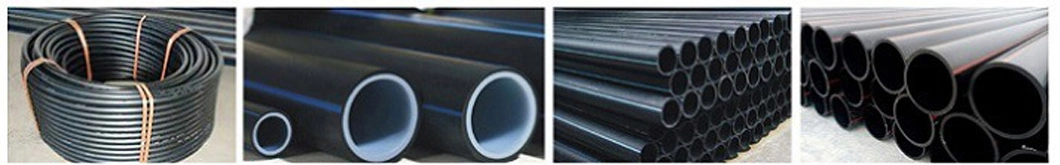

PE pipe production line is primarily used in the manufacturing of PE pipes with diameters ranging from 16mm to 1200mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two- or three-layer spiral mold for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

Features

The optimum spiral structure-feeding throat highly improves the output of extruder;Accurate temperature control system ensures materials melting performance;Unique screw design achieves better plasticizing and high-quality products;Precisely designed gearbox with a high torsion guarantees stable running;"H" shape frame to decrease vibrating of extruder;Advanced PLC operation system realizes synchronization and automation;Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks;Offer stable haul-off unit with 2-12 caterpillars;Provide saw & chip-free cutting options;Low energy consumption, excellent performance, and easy maintenance.

Product Parameters

| Item/Model | GF63 | GF110 | GF160 | GF250 | GF315 | GF630 | GF800 |

| Diameter range/mm | 16-63 | 16-110 | 50-160 | 50-250 | 110-315 | 315-630 | 400-800 |

| Claw number of haul off/pcs | 2 | 2 | 2 | 3 | 4 | 6 | 8 |

| Pulling force/KN | 6 | 8 | 11 | 20 | 30 | 40 | 50 |

| Pulling speed/meter/minute | 15 | 12 | 8 | 9 | 4 | 2 | 2 |

Remarks: all information above is only for refererence; please gather the exact data by contacting us.

Detailed Photos

Machining Equipment

Electric Components

Business Cooperation

More Products For Option

Our Contact