PVC Pipe Machine Plastic Extrusion Line UPVC Tube Production Line High Automatic for PVC Pipe Extrusion Line

Description

Basic Info

| Model NO. | Sevenstars |

| Assembly Structure | Separate Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Transport Package | Film Packing |

| Specification | CE certification ISO9001: 2015 |

| Trademark | sevenstars machinery |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 100 Set/Year |

Product Description

Product Description

Our PVC pipe production line adopts advanced technology from Australia and Taiwan. We can customize various PVC pipe production lines according to the pipe standards of various countries in the world. Our pipe diameter range is: 12mm-1200mm, from large water supply pipes to small cables We can customize the tube. Our PVC pipe production lines are spread all over the world and have a large customer base. We will provide all customers with on-site installation, commissioning, training, etc.Feature1) Main machine uses PVC high efficiency screw, and notch feeder with powerful waterCover cooler, which has greatly improved transmitting capability and ensuredExtruding. DC running electric machine with high-quality speed adjuster2) Applied for the basket-shaped composite electric head for processing polythene,Which not only ensures the stability of high efficiency extruding, but also achievesThe minimum stress and highest pipe quality brought by low melting temperature3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paintCooler gullet, which improve the finished product passing rate, and meetThe requirements of high speed manufacturing. Vacuum calibrating platform and coolerGullet are all made of stainless steel4) Adopting multi-track traction, through the central motor to run all the tracksTo reach same height, and ensure roundness of pipes5) Adopting fully automatic control system with high precision, reliable operation,Easy and convenient handling6) Suitable pipe diameter: 16 - 630mm

Product Parameters| Model | Dia | Max speed | Power | line length |

| PVC50 | 16-50 | 10 | 85 | 20 |

| PVC63 | 16-63 | 10 | 60 | 20 |

| PVC110 | 50-110 | 10 | 70 | 24 |

| PVC160 | 63-160 | 5 | 90 | 24 |

| PVC250 | 110-250 | 3.5 | 120 | 28 |

| PVC315 | 160-315 | 3 | 160 | 28 |

| PVC450 | 240-450 | 1.5 | 200 | 36 |

| PVC630 | 315-630 | 0.9 | 230 | 36 |

Application

1).Water supply, drainage pipelines in building;2).Rainwater drainage pipelines in building;

3).Electrical wiring pipe in building;

4).Air conditioning condensate water systems.

Plastic extruder machine1.World famous brand electrical component such as Siemens, ABB etc .2.High torque gearbox with adopts NSK/SKF bearing; 3.Bimetallic screw and barrel; 4.Intelligent PLC controlling system with human-friendly interface.Mould

1.Material of mold body is Steel 45# ,harden treated and polished.2.Material of inner mould parts is 40Cr.3.The material of calibration bushing is Stannum bronze.4.The diameter can be customized.

Vaccum calibration water tank

Function:1.Calibrating the pipe outer diameter and cooling pipe.2.The material of water tank is stainless steel 304.

Hauling off machine1.Function :haul off PE pipe stably and synchronal with extruder speed.2.Clamping mode is pneumatically.3.speed adjusting mode is frequency conversion.

Cutting machine

Feature: 1.PLC control, automatic cutting and counting,easy for production operation.2. adopt famous Airtac air cylinder, steady performance, reduce maintain cost.

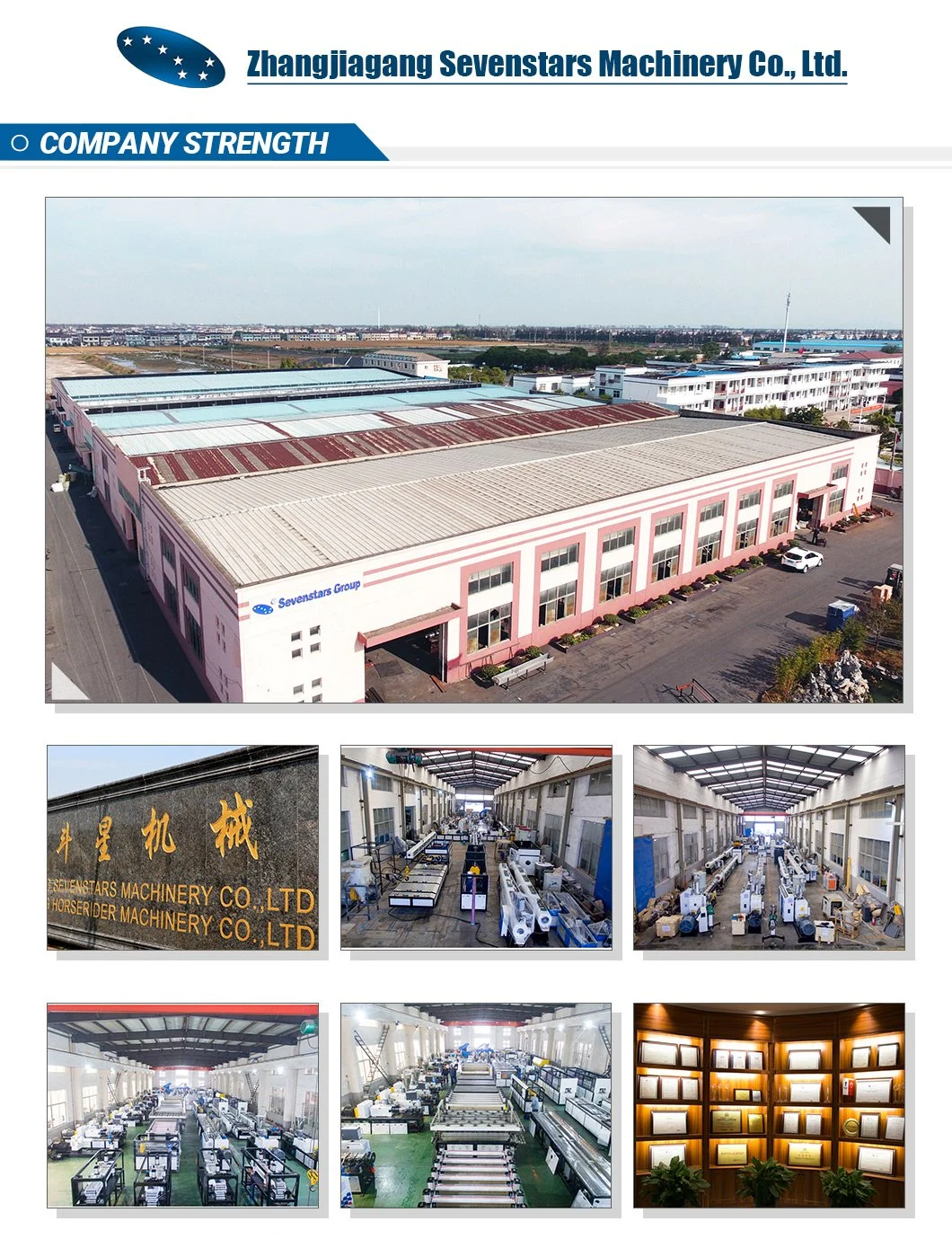

Company Profile

Zhangjiagang Sevenstars Machinery is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines. For plastic machines, our main products include: big-mouth PVC pipe extrusion production lines, PE big-mouth for gas, water supply extrusion production lines, PET bottle recycling line PE/PP film recycling line PVC/WPC foam board extrusion line PVC/WPC profile extrusion line PP hollow sheet extrusion line HDPE/LDPE pipe extrusion line PPR PIPE extrusion line plastic extruders, high speed mixers and various plastic auxiliary machines. Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

1. who are we?We are based in Jiangsu, China, start from 2006,sell to Africa(15.00%),Mid East(12.00%),South America(10.00%),Eastern Europe(10.00%),Southeast Asia(10.00%),Southern Europe(10.00%),South Asia(10.00%),Domestic Market(10.00%),North America(5.00%),Western Europe(4.00%),Central America(2.00%),Oceania(00.00%),Eastern Asia(00.00%). There are total about 51-100 people in our office.2. how can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.what can you buy from us?Plastic Recycling Line,Plastic Pelletizing Line,Plastic Board Production Line,Plastic Profile Extrusion Line,Plastic Pipe Extrusion Production Line4. why should you buy from us not from other suppliers?We have more than 10 years experience in fabricating the machine, we can fabricating the machine according to customer request. we have good after service.5. what services can we provide?Accepted Delivery Terms: FOB,CFR,CIF,EXW;Accepted Payment Currency:USD,EUR,CNY;Accepted Payment Type: T/T,L/C,Escrow;Language Spoken:English,Chinese

Our Contact