PVC Pipe Making Pipes Processing Machine UPVC Plastic Tube Machine Electric Extruding Production Line

Description

Basic Info

| After-sales Service | 1 Year |

| Warranty | 1 Year |

| Type | Pipe Extruder |

| Plastic Processed | PVC |

| Product Type | Extrusion Molding Machine |

| Feeding Mode | One Feed |

| Assembly Structure | Integral Type Extruder |

| Screw | Single-Screw |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Transport Package | Wood Box and Film |

| Specification | SJZ65/132 |

| Trademark | Wings |

| Origin | Qingdao |

| HS Code | 84772090 |

| Production Capacity | 30 Lines / Year |

Product Description

PVC Pipe Making Pipes Processing Machine UPVC Plastic Tube Machine Electric Extruding Production Line

Qingdao Wings Plastic Technology is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines, plastic production line. Our plastic extrusion lines based on Plastic Extruders: Single Screw Extruder, Conical Twin Screw Extruder and Parallel Twin Screw Extruder. Our plastic making machine can make many kinds of plastic productions like: PVC pipe, CPVC pipe, PE/HDPE/PE-RT pipe, PP-R pipe,plastic foamed profile, WPC profile and panel, wood plastic composite and so on. Plastic Extruder is widely used in Plastic industry. It is the main part of Plastic Pipe Extrusion Line, Plastic Profile Extrusion Line, Plastic Recycling Line and Plastic Granulating Line. Our plastic extruder use good quality screw in plastic machinery. Our plastic machine have long-life.

We can customize various PVC pipe production lines according to the pipe standards of various countries in the world. Our pipe diameter range is: 12mm-1200mm, from large water supply pipes to small cables We can customize the tube. Our PVC pipe production lines are spread all over the world and have a large customer base. We will provide all customers with on-site installation, commissioning, training, etc.

Produce process for PVC Pipe :PVC powder + additive → mixing → spring feeding → twin screw extruder → mould and calibrator → vacuum forming machine → haul off machine → cutting machine → stacker

Twin Screw ExtruderHigh production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality sheet extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel >940, the surface of screw is chromeplated Feeding bush with water cooling system

Pipe Extrusion Die head

The die head is made by 40Cr moulds materials.Using mica heating way- Spacious flow channel design to guarantee highextrusion capacity and good melt.- Optimized temperature control and flow channeldesign, precise melt temperature control.

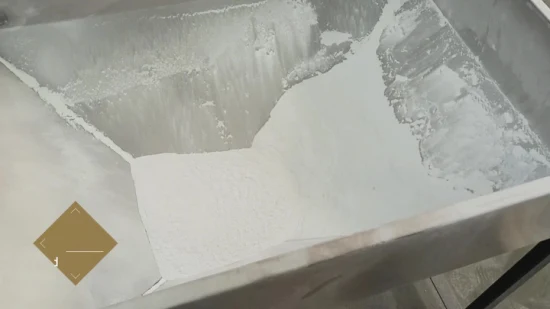

Pipe Vacuum Tank

It is adopted stainless steel materials, high quality vacuum and water pumb. Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling.Haul off unit

it could be 2 claw, 3 claw, 4 claw, 6 claw according different pipe diameters.For the different pipe size and different speed requirement, Wings Plastic developed kinds of haul-off unit accordingly.The haul-off unit equiped with single motor drive or every caterpilar with seperate motor drive , there is the belt tyope haul-off unit,stable hauling.For the large diameterpipe, a pipe winch device is equipped to the production line to reduced the waster material.Cutting Machine

It could be no dust cutting,planetary cutting,chamfer cutting,saw cutting according customer request.Cutting type:automatic meter counting cutter.Stacking Machine

Length 6000mm

Stacking way:Pneumatic way

Mixer

It is working for mixing pvc powder materials with additives according formula.It could be 200/500mixer,300/600mixer,500/1000mixer always.You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspect the running production line.)3. Delivery.4. We will provide after-sales service:(1) Field installation and commissioning;(2) Field training your workers; (3) Field maintenance and repair service ;(4) Free Spare Parts ;(5) Video/Online technical support.

Prev: 2023 Hot Sale Small/Large Diameter Copper Tube High Frequency Pipe/Tube Welding Production Line

Our Contact