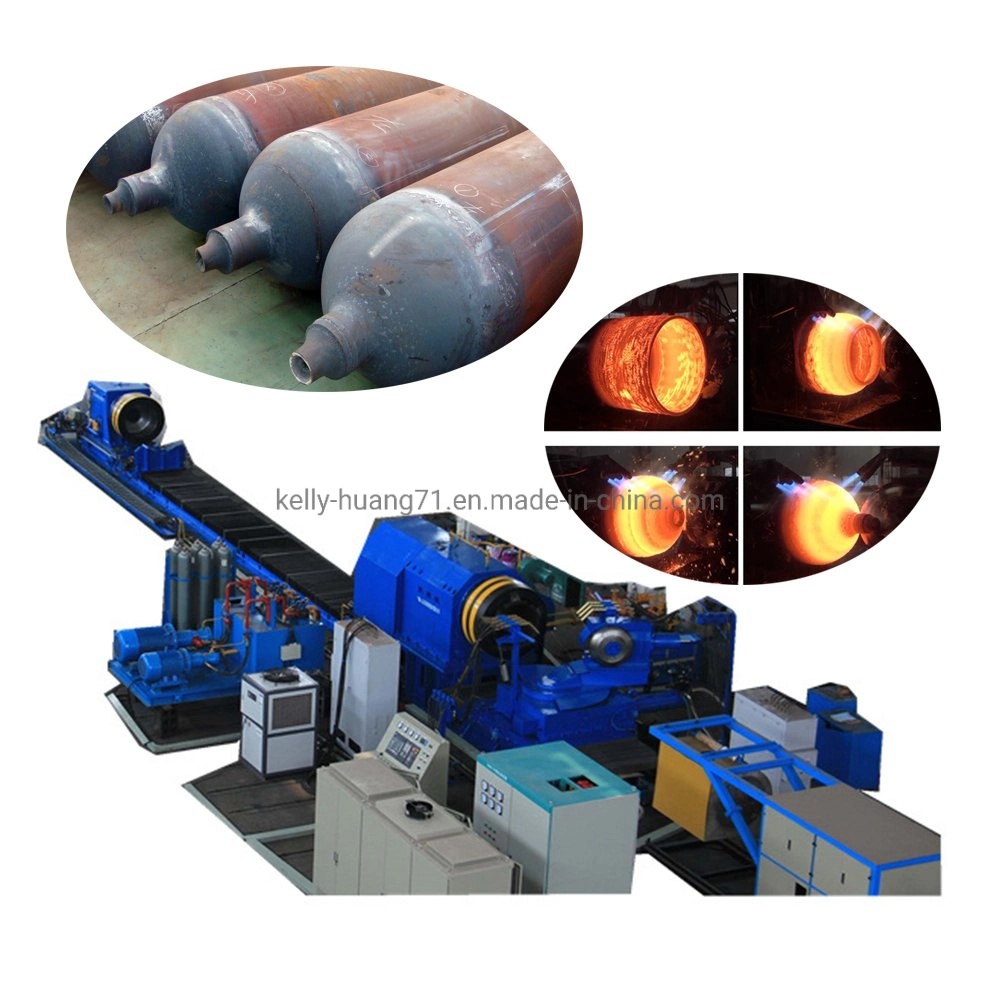

Roller/Rolling Wheel Type Pipe End Bottom Thg510 Hot Spinning Closing Machine for Gas High Pressure Cylinder

Roller/rolling wheel type Pipe End Bottom THG510 Hot Spinning Closing Machine For Gas High Pressure Cylinder THG406 CNC

Description

Basic Info

| Metal Material | Steel |

| Spinning Deformation Condition | Hot Spinning |

| Spinning Belt Wheel Type | Rolling V Type Belt Wheel |

| Spinning Wheel Number | Double |

| Finished Product | Pipe |

| Finished Product Shape | Cylinder Shape |

| Max. Cylinder Diameter | 406mm |

| Mini Cylinder Diameter | 232mm |

| Max. Cylinder Length | 2000mm |

| Mini. Cylinder Length | 750mm |

| Wall Thickness of Steel Pipe | 5-15mm |

| Spindle Motor | 144kw (DC) |

| Axial Stroke of The Slider | 65mm |

| Radial Stroke of The Slider | 17mm |

| Radial Clamping Force | 1200kn |

| Spindle Speed (Adjustable) | 0-600rpm |

| Axial Stroke of The Mold | 450mm |

| DC Drive | Siemens |

| Maximum Axial Force | 246kn |

| Maximum Axial Feed Speed of The Die | 200mm/S |

| Maximum Rotary Wheel Torque | 65kn.M |

| Transport Package | Plywooden Box or Steel Tray |

| Specification | 4027*1980*2450 |

| Trademark | LTM |

| Origin | Jiangsu, China |

| HS Code | 8463900020 |

| Production Capacity | 5000PCS/Year |

Product Description

Roller/rolling wheel type Pipe End Bottom THG510 Hot Spinning Closing Machine For Gas High Pressure Cylinder

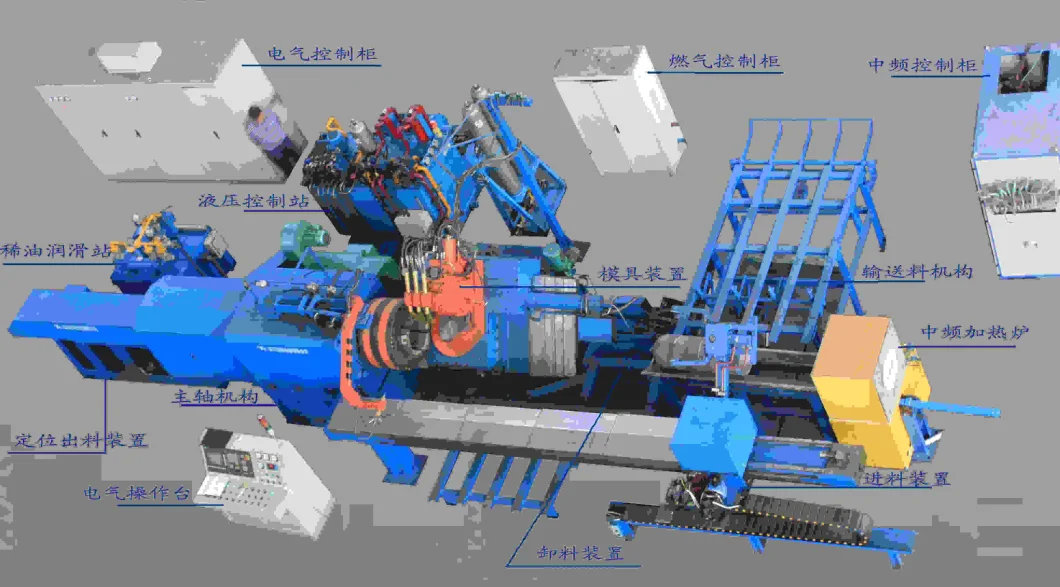

| Equipment center height | 1250 mm (spindle center from the bottom plane of the fuselage) |

| Spindle motor | 144KW (DC) |

| Axial stroke of the slider | 65mm |

| Radial stroke of the slide | 17mm |

| Radial clamping force | 1200KN |

| Spindle speed | 0-600rpm adjustable |

| DC Drive | Siemens |

| Maximum axial force | 246kn |

| Maximum axial feed speed of the die | 200mm / s |

| Maximum speed of rotary wheel rotation angle | 30° / s |

| Maximum rotary wheel torque | 65KN |

| Wave Angle | 0-100 |

| Hydraulic motor | 90kw |

| Scale speed reversing valve | Italian ATOS |

| Electronic control system | Siemens 828D |

| Heating power at the pipe end | 500KW / 1000Hz |

| Pneumatic load | 6bar |

Hot spinning Making ProgressPipe delivery- feeding --rotation heating ---unloading-- feeding--hot spinning--unloading.

| LTG325 | LTG406 |

| Processing diameter | DN219-325 | DN325-406 |

| Processing length | 800-2000mm | 800-2000mm |

| Processing thickness | 5-15mm | 5-18mm |

| Central height | 1100mm | 1200mm |

| Main engine power | 90kW | 144kW |

| Rolling wheel swing angle | 100° | 100° |

| Spindle speed | 700rpm | 700rpm |

| Control methods | CNC | CNC |

| Machine dimension | 1600x2000x1420mm | 1800x2000x1600mm |

We are professional manufacturer of CNG/LPG/LNG cylinders manufacturing machine for over 30 years. our machines have been exported to Russia, Ukraine, USA, UK, Turkey, Australia, Kenya, Egypt, India etc...FAQQ: How can we guarantee quality?

A: Always a pre-production sample before mass production; Always final Inspection before shipment;Q: What can you buy from us?

A: All the machine for the CNG cylinder production line

Q: Why should you buy from us not from other suppliers?

A: Wuxi Longterm Group is group corporation which are professional supplier of cable, LPG gas cylinder, steel drum, LNG and CNGmachinery with more than 25 years of experience and a strong professional R & D teamQ: What services can we provide?

A: Online technical support, On-site installation, Spare parts...We need to know the following information to make the quotation to you:1. The diamater and technical drawing of the cylinder.2. Daily capacity.

Prev: Stainless Steel Sheet Metal Fabrication Stamping Parts with OEM Service

Next: Hot Sale Pipe Channel Profile Round Tube Pipe Bending Machine Section Rolling Machine

Our Contact

Send now