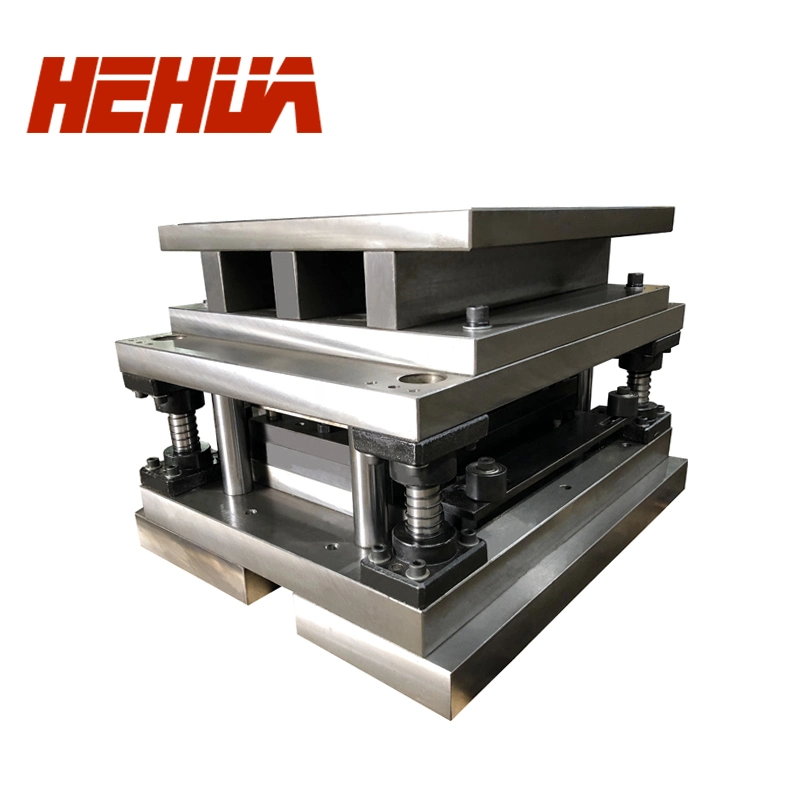

Stamping Die Stainless Steel Stamping Mould Sheet Metal Punching Die Manufacturer

Description

Basic Info

| Model NO. | oem |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | EDM Milling |

| Milling Speed | Normal Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| Quality | as Your Require |

| MOQ | 1 Set |

| Certification | ISO9001:2015 |

| Transport Package | as Your Require |

| Specification | OME Parts |

| Trademark | Hehua |

| Origin | China |

| HS Code | 8207201000 |

| Production Capacity | 50/Month |

Product Description

:| Product Name | stamping mould/mold/die |

| Product Dimension | OEM |

| Processing Type | stamping, surface treatment |

| Tolerance | as per customers' requirement. |

| Material Standard: | ISO, DIN, ASTM, UNS, AISI, JIS, BS, NF |

| Materials available | steel, stainless steel, aluminum, brass, etc. |

| Material Thickness | as per customers' requirement. |

| Surface Treatment/Finish | Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Paint, Powder Coating, Polish etc., |

| Heat treatment capability | Annealing, Normalizing , Nitriding, Tempering ,Carbonitriding |

| capability | Carburizing and induction hardening etc., |

| Industry Of Use | Used in metallurgy, automobile, aero, chemical, ship hardware, and other industries |

| Quality Assurance | ISO 9001:2016, IATF 16949:2016, RoHS |

| Sample Lead-time | Within 1day for samples available from our stock About 1-2weeks for custom samples |

| Mass Production Lead-time | 3-7 weeks after receiving deposit. |

| Price Terms: | EXW/FOB/CFR/CIF Shanghai or any other airport or seaport, China |

| Payment Terms | 30% deposit, balance against B/L copy |

| Modification | Mould modification until the customers satisfy it. |

| Inspection | In-house or third party, all the products are strictly inspected by skilled QC |

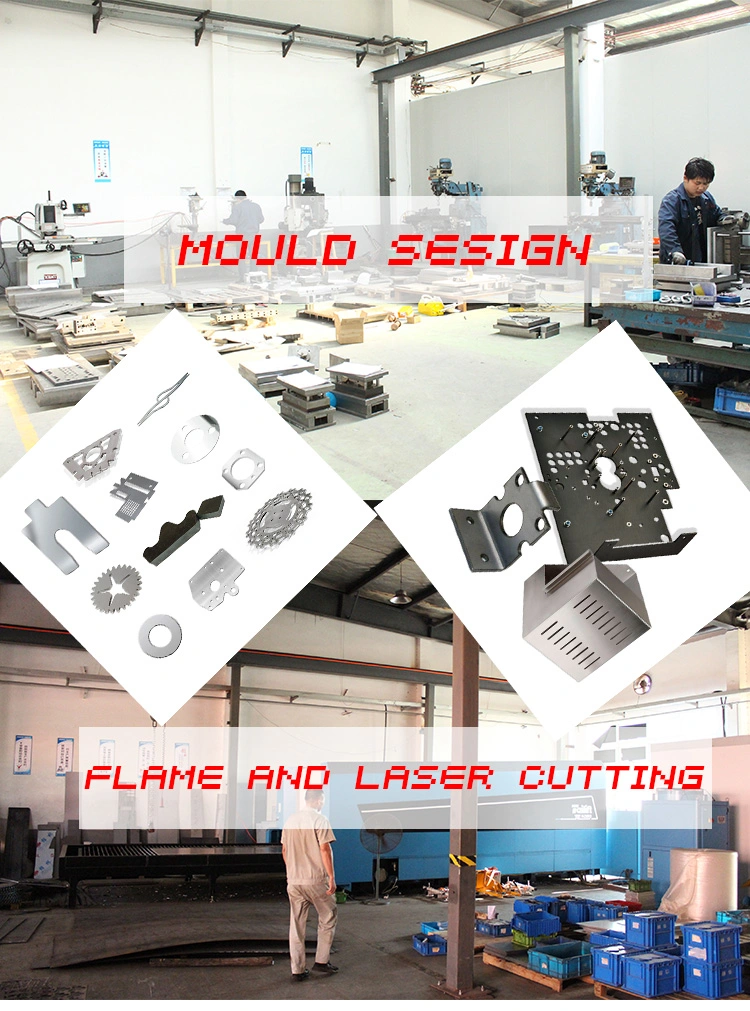

| Design: | We use the most advanced mould design software Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Country of Origin | China (mainland) |

| Main Export Markets | Europe, America, Mid East, Asia, Africa etc., |

| Service Type: | OEM & ODM |

| Business Type: | Manufacturer, Exportor |

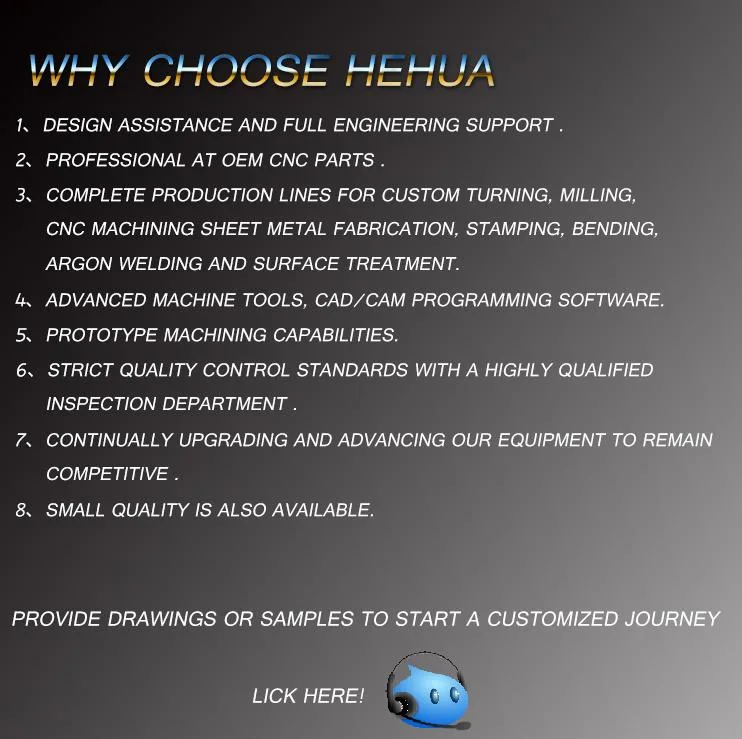

| Advantages | Expert in producing OEM parts: metal stamped, machined, deep drawn and sheet metal formed parts with various finishing Geographical location advantage: our office in Shanghai which can help us to offer better services for the customers from all over the world Our factory is located in Shanghai, nearby Shanghai ports, which can save transportation time and cost Employing reliable rockers and utilizing advanced machines: we have a full range of machinery and equipment for punching, welding, CNC, milling and grinding. We also have experienced technicist who are engaged in technical development. Our skilled workers, professional engineers, R and D center and excellent foreign trade team always keep the passion to support our customers |

Product package:

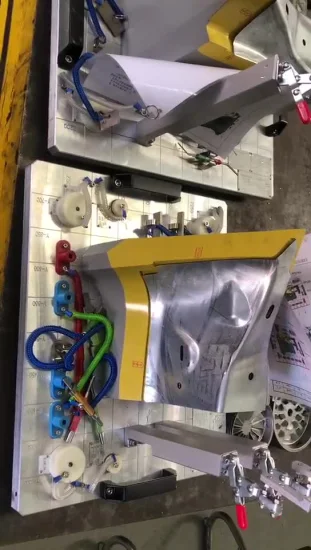

Workshop and equipment related:

Qulification

Happy time with customer

FAQ

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping parts for more than 15 years.

Q: What are your main products?

A: We specialize in manufacturing metal stamping die ,metal stamping parts.sheet metal parts,cnc machining part and welding structural parts etc.

Q: What is surface treatment do you have?

A: Dacromet ,powder coating,Zinc plated, nickel plated, tin plated, brass plated, silver plated, gold plated, anodizing, salt fog test etc.

Q: Can I get the samples?

A: Yes, sample is free with stamping mould order.

Q: What is the MOQ?

A:The MOQ is 1 set.

Q:What's the delivery time?

A:The stamping mould is 20 days after payment.

Q: What's your payment term?

A: we advise 50% T/T deposit, balance be paid after sample confirmation.

Q: Do you received OEM/ODM?

A: YES. We have more than 15years OEM experience.

Prev: Bending Machine V Opening Adjustable Die Mould, Roll Bend Die, Wingbend Die

Next: Round Brass Bar 6 Holes High Density Graphite Mold/ Brass Bar Casting Die

Our Contact