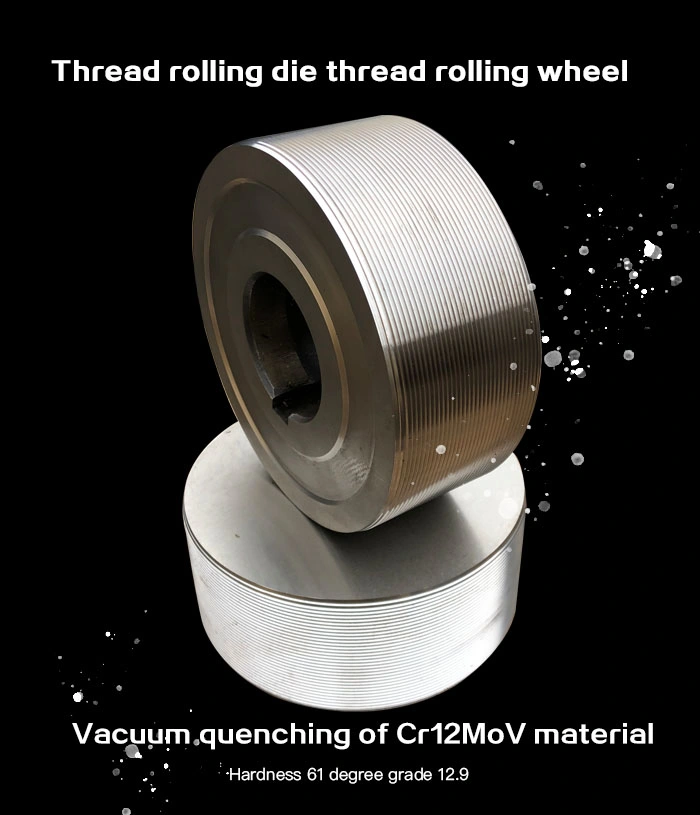

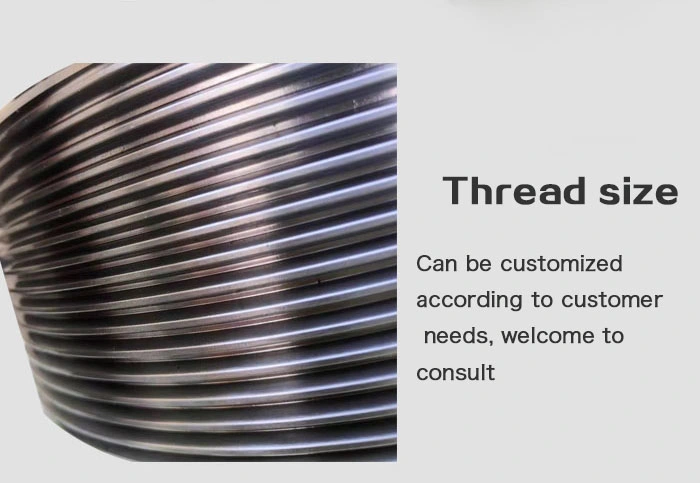

Thread Rolling Machine Accessories Mould Mould Flat Die String Modem36

Package size per unit product 18.00cm * 18.00cm * 18.00cm Gross weight per unit product 16.000kg Precautions 1. The wire

Description

Basic Info

| Model NO. | 54holes 80 thick |

| Hardness | 61 |

| Grades | 12.9 |

| Texture of Material | Cr12MOV |

| Transport Package | Wooden Case |

| Specification | 54holes 80thick |

| Trademark | jieyu |

| Origin | China |

| Production Capacity | 50000pieces/Year |

Packaging & Delivery

Package size per unit product 18.00cm * 18.00cm * 18.00cm Gross weight per unit product 16.000kgProduct Description

Precautions1. The wire rolling machine tool has poor accuracy, large vibration and is used under abnormal operation;

2. The misalignment of the wire rolling die causes axial displacement of the rolled part, and the tooth lines are subject to shear and extrusion stresses;

3. The size of rolled thread blank is uneven, the surface is not cleaned, and there are grinding wheel foam, oxide skin and dirt;

4. The hardness of the rolled parts is uneven (Grade 8.8 bolts shall be 27~30HRC; Grade 10.9 bolts shall be 35~37HRC), to prevent the untempered quenched parts with high hardness (50~55HRC) from being mixed into the tempered parts due to poor management, and the hardness is similar to the edge hardness of the thread rolling wheel, resulting in edge collapse.

5. No lubricant is added during rolling, resulting in dry friction, which makes the temperature of the tooth tip rise sharply to exceed the tempering temperature of the thread roller, and the tooth grain is softened due to excessive tempering, resulting in tooth recession and tooth stacking failure;

| texture of material | cr12mov |

| grades | 12.9 |

| hardness | 61 |

Our Contact

Send now