Zinc Galvanized Steel Sheet Leveling and Cutting Machine for Straightening Metal

Package size per unit product 400.00cm * 150.00cm * 150.00cm Gross weight per unit product 3500.000kg Zinc galvanized st

Description

Basic Info

| Model NO. | leveling and cutting |

| Voltage | 380V |

| Automatic Grade | Automatic |

| Principle | Cold Roll Leveling |

| Certification | ISO9001, CE |

| Warranty | 24 Months |

| Customized | Customized |

| Condition | New |

| Name | Zinc Galvanized Steel Sheet Leveling and Cutting M |

| Materia Thickness | 0.8-1.5 mm |

| Materia Width | 1200 mm |

| Motor Power | 7.5 Kw |

| Cutting Type | Hydraulic |

| Leveling Shafts | No. 45 Steel |

| Speed | 10-15m/Min |

| Control Mode | PLC Control |

| Cutting Blade | Cr12 MOV |

| Length Tolerance | ±1 mm |

| Color | Custermized |

| Diameter of Shaft | 120 mm Solid |

| Transport Package | Standard Packaging |

| Specification | 4000*1500*1500 mm |

| Trademark | no |

| Origin | Hebei, China |

| HS Code | 84552210 |

| Production Capacity | 200 Stes/ Month |

Packaging & Delivery

Package size per unit product 400.00cm * 150.00cm * 150.00cm Gross weight per unit product 3500.000kgProduct Description

Zinc galvanized steel sheet leveling and cutting machine for straightening metalSheet metal leveling machine levels all kinds of uneven steels by physical principle and cuts them to the desired length, facilitating subsequent production and processing. The machine is an important part of some building material production lines. The configuration of the machine depends mainly on the thickness, material and characteristics of the original material. The machine can be applied to a variety of cold, hot-rolled plate leveler.| Technical Parameter | ||

| 1 | Dimensions | 4000*1500*1500 mm |

| 2 | Weight | 3500 kgs |

| 3 | Quantity of shafts | up 7 pcs, down 7 pcs |

| 4 | Material of the cutting balde | Cr12, quenched treatment 58-60 ºC |

| 5 | Rolling Material | High quality bearing steel |

| 6 | Diameter of rollers | 120 mm |

| 7 | Main structure of the machine | 400 H Beam |

| 8 | Side panel of machine | 20 mm |

| 9 | Chain | 1inch |

| 10 | Motor power | 7.5 kw |

| 11 | Pump station motor | 4 kw Lichao |

| 12 | Productivity | 10-15m/min |

| 13 | Thickness of the plate | 3-4 mm |

| 14 | Length tolerance | ± 1mm |

| 15 | Touch screen | Delta |

| 16 | Voltage | 380V 50Hz 3 phases or as customer's need |

| 17 | Transmission type | Gear drive |

| 18 | Suitable to process | GI/ GL/ PPGI/ PPGL/ Aluminum coils |

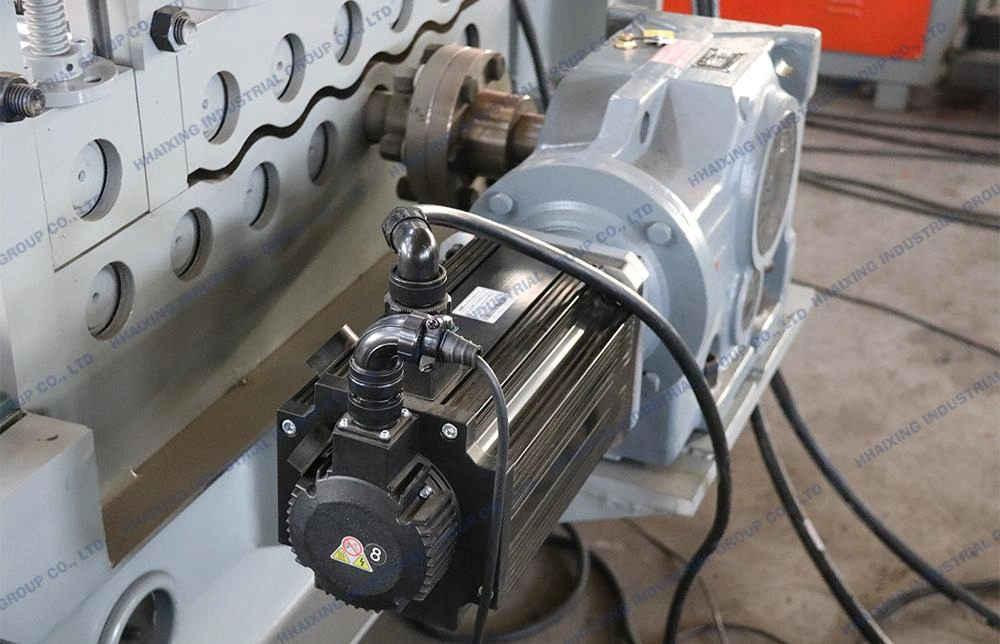

Picture Details:

Zinc galvanized steel sheet leveling and cutting machine for straightening metal after sales services1. Warranty :two years and technical support for whole life of the equipment2. Delivery time: Within 25 days after deposit receipt3. Installation and training If buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.About us

Tianjin Haixing Imp & Exp Is a professional manufacturer and exporter which has its own factory and also cooperate with several production factories and associated enterprises, concerning with the design, development and production of cold roll forming machines,material of machines. It is located in northwest of Tianjin, China . As a long history of cold roll forming machine production base. For example :color steel roofing sheet roll forming machines, C&Z Purlin machine, steel roof tile roll forming machines, floor deck forming machines, EPS sandwich panel roll forming machine, highway guardrail forming machine, shearing machine, bending machine, slitting machine.All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system. Based on our advanced research and commercial team, we are able to research and development, manufacturing and sale of standard and non-standard cold roll forming equipment for our clients world widely. We would like to invite you come and join us to build our mutual benefit.

Prev: Steel Wire Straightening and Cutting Machine for High Carbon Steel Wire and Low Carbon Steel Wire

Next: Glazed Steel Plate Roof Wall Roll Forming Machine for Sale

Our Contact

Send now