Housingless Mill Stand From Fuzhou City/ Steel Rolling Mill

Description

Basic Info

| Model NO. | 610/530/470/370/350 |

| Roll Position | Vertical |

| Customized | Customized |

| Certification | SGS, ISO |

| Power Source | Electric |

| Transport Package | Nude Packaging and by Seea |

| Specification | Steel |

| Trademark | Jinquan in Chinese |

| Origin | Fuzhou, China |

| HS Code | 8455213000 |

| Production Capacity | More Than 50000 Tons of Equipments/ Year |

Product Description

Hi, welcomeHorizontal or vertical housingless stands mills used for roughing or intermediate mills

| Model No. | Roller barrel Φmax/Φmin*Length |

| 700 | Φ700/600X800 |

| 610 | Φ610/530X760 |

| 530 | Φ530/460X760 |

| 470 | Φ475/400X650 |

| 370 | Φ370/330X650 |

| 350 | Φ350/320X650 |

Product Description

Short stress line mill is also called housing less mill, with a lot of advantages such as light weight, high stiffness, quick roll change, it widely used in continuous medium and small rolling mill. Short stress line mill train consists of the mill stand body(stand cartrige), movable base frame, fixed base, universal coupling and bracket, vertical mill stand change trolley, union gear reducer, main drive motor, etc. Mill train can be arranged by horizontal or vertical layout for twist free rolling. Mill stand body is mainly consists of screwdown assembly, mill roller system assembly, pull rod assembly, guide frame assembly, etc. The mill stand body specification are 610, 530, 470, 370 type, etc. According to different position and the size of the roll mill layout.

Company profile

| Company name | Fujian Jinquan Group, the Group consists of Fuzhou Jinquan Metallurgical Machinery, Fujian Tianfeng Machinery And Fuzhou Zhongfu Water Meter |

| Histrory | More than 30 years development in the business of metallurgical industry of steel rolling mills, we have built around 1100 steel rolling mill production lines around the world. |

| Basic information | The group has more than 1000 employees, numbers of professinonal and technical personnel are near to hundred, covers an area of total of nearly 96000 cubic meters, |

| Main product(manufacturer) | We mainly produce steel rolling mills, and Turn Key project service, offering whole package service from designing, manufacturing, installation, commissioning, of course after-sale service, to our customers of steel bar rolling mills production mill, wire rod production line, section steel hot rolling production lines(its finshed products are like angle steel, channel steel, square steel etc...) and steel strip production line and their electric control equipment, also CCM (continuous casting machine) etc... |

| To our potential customers | Dear, if you plan to enter into steel rolling mill business, or you need the rolling mill equipments for products like steel rebar, bar, wire rod, steel flap, steel channel, steel H beam, etc, and you are welcomed to share your questions or problems about metallurgical industry, we are at your service at any time. |

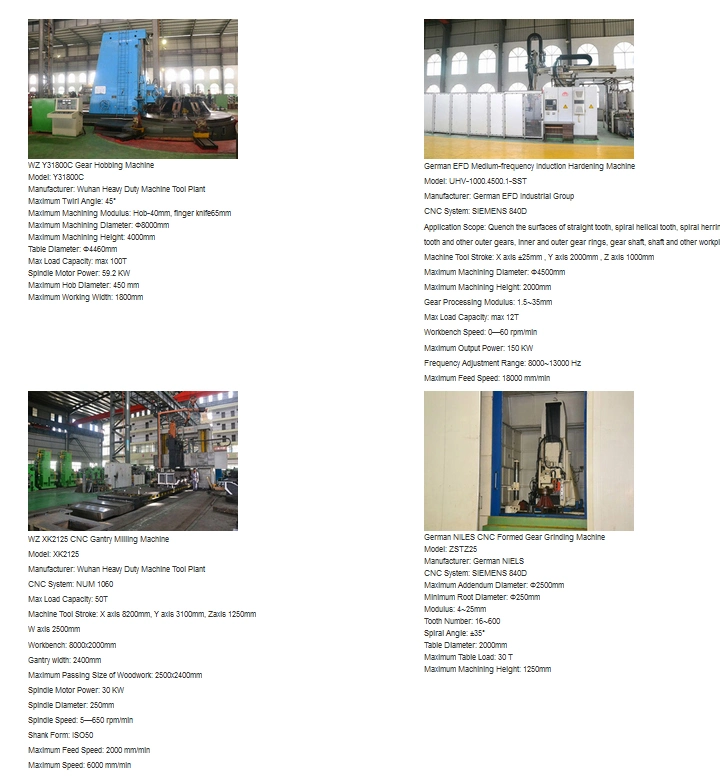

CertificateTechnical equipment

Our advantages

1: Rich experience: The Jinquan Group since the start-up in 90's, it has been tightly involved in the iron and steel industry, we have built 1100 steel rolling mill lines all over the world. 2: Technology and Equipment owned: Numbers of professinonal and technical personnel are near to hundred, he has more than 600 small and medium-sized advanced equipments to produce rolling mill machines and provide customers with rolling mill machines. 3: Staff principle: Customers first. And we will do our best to provide you with good service, and stand in customers's shoes to think questions.

Custom-designed according to the special needs of mature production line:

According to the needs of users, to provide technical solutions and other services security: Offer single piece of rolling mill machines and also whole package service from designing -manufacturing -installing-commissioning for production line, like wire rod mill, bar mill, section steel mill(like, angel steel, square steel, flap steel, I beam, H beam, etc...) and strip steel mill. 1: Total plan layout and detailed process equipment layout, production technology; 2: Our engineers is at your service at any time. 2: On-site equipment installation, instruction. 3: The production line commissioning technology guidance. 4: Required staff technical training; 5: After-sales service will be guaranteed. 6: Quality warranty will be guaranteed. 7: Other detailed services, like water system equipments, compressed air system equipments, firefighting system, etc., will be showed on quotation.

Service Assurance

The Jinquan Group the face of hundreds of users around the world have established efficient and professional service system. According to the customers' needs and the actual situation to tailor the optimal solutions and provide the best quality equipment products, bear the guidance of a full set of production line equipment of metallurgical machinery installation, commissioning, maintain production, and implementation of the tracking service guarantee spare parts supply, provide timely and efficient service to customers around the world.

Pre-sale: (1) customers with Division I professional to communicate and understand the needs of customers. (2) technical staff to the the user site planning venue to provide the best solution. (3) the optimal design of the hardware based on customer demand;

Sales: (1) to provide the best quality products, the two sides of the acceptance of the product; (2) to provide customers with a list of spare parts; (3) to help customers develop the best on-site construction program.

Aftermarket: (1) The to assign professional engineering staff, arrived at the scene to guide the installation and commissioning; (2) Long-term real-time tracking of user field devices use to provide timely and effective life-long service to the user.

We have always been committed to providing customers with the best quality service, we will strive to provide better service for customers.

Thanks for your watching.

Our Contact