Plastic PE HDPE PVC Water/ Gas /Electric Conduit Pipe/Tube Making Machine / Single Screw Extruder/ Twin Double Screw Extruder /Plastic Pipe Extruder Machinery

Description

Basic Info

| Model NO. | sj90/38 single screw extruder |

| Customized | Customized |

| Condition | New |

| After-sales Service | 1 Year |

| PE Pipe Diameter | 20-315mm |

| Pipe Layers | ABA /ABC |

| Pipe Raw Material | PVC PP PE PPR |

| Pipe Usage | Water /Gas Supply |

| Transport Package | Film Package by Container |

| Specification | 20-315mm |

| Trademark | wangyuan |

| Origin | China |

| HS Code | 84779000 |

| Production Capacity | 100 Sets |

Product Description

qingdao cuishi plastic machinery make the pipe line since 1999 professional manufacturer for 20-1000mm PE pipe production line PE pipe making machine

Plastic Twin/Single Extruder/Extrusion PVC PE PPR PP HDPE PipeAgriculture Water/Gas /Drainage/ Water Supply Pipe Line/extrusion lineHDPE Plastic Water Supply Pipe Making Machinery adopt high speed extruder with high efficient,energy saving. The extruder have water recycled inside with metering material loading device; The single-screw extruder and the traction machine adopt imported AC frequency conversion speed regulating device, and the vacuum pump and traction motor are all made of high quality products. The tractor is driven by two claws, three claws, four claws, six claws, eight claws, ten claws, and twelve claws. Available with chipless cutting, saw blade cutting or planetary cutting, the unit has reliable performance and high production efficiency.

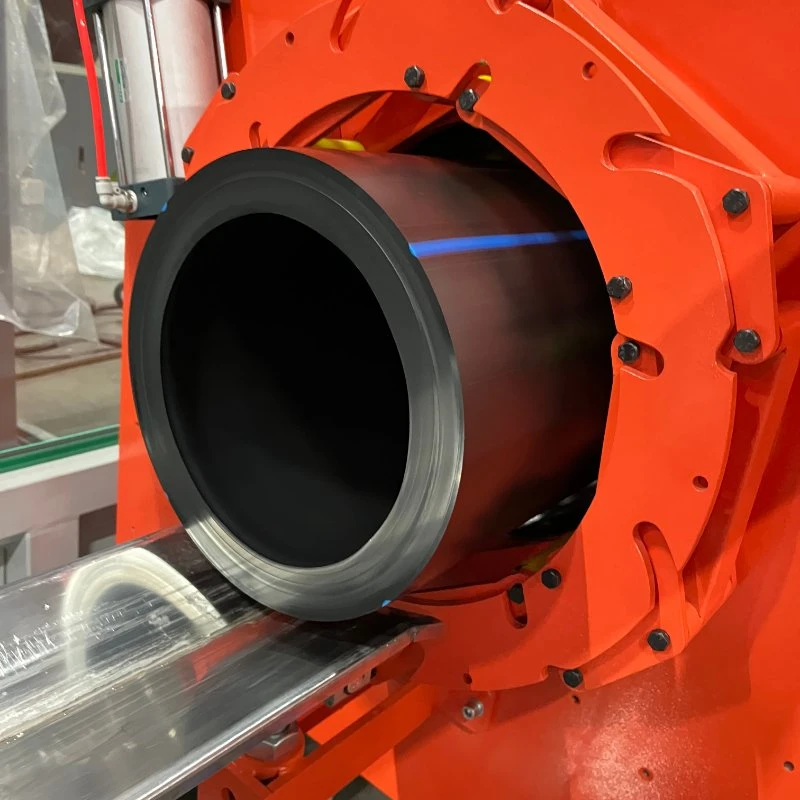

Pipe Extrusion Die head the die head is made by 40Cr moulds materials.Water Pipeline HDPE / LDPE Pipe PE HDPE LDPE LLDPE Plastic Pipe Manufacturing Line

Plastic PPR, HDPE, PE, UPVC Electric Water Conduit Pipe Tube Extrusion Line/ PVC Single Wall Corrugated Pipes Making Machine

p pe one layer or thress layers pipe making machinehigh efficiency single screw extruder advatages:

- The extruder has the following advantages: high plasticization rate, uniform melt and continuous production stability. High performance gearbox reducer. High torque, long life and low noise.

- 132KW servo permanent magnet motor saves 15% power

- Siemens PLC control

- Frequency conversion control of vacuum sizing box, saving 30-40% of electricity

- The inner and outer layers are separated by two 65 extruder, this way can better control the layering. also be used for different purposes, such as three layers of different materials or different colors.

HDPE|PE|PP|PPR|CPVC/LDPE Conduit Tube/ Water Sewage Pipe Extrusion Production Line

PE pipe production line is primarily used in the manufacturing of PE pipes with diameters ranging from 16mm to 1200mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two- or three-layer spiral mold for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.pp pe one layer or thress layers pipe making machineextrusion mold advatages:- High-speed molds and sizing sleeves

- The inner and outer layers are separated by two 65 extruder, this way can better control the layering. also be used for different purposes, such as three layers of different materials or different colors.

Plastic PE/PP/PPR/HDPE/LDPE Water& Electric Conduit Pipe/Tube Extrusion/Extruding Making Production Line Machine

Plastic PE PP PPR Extruder Machine, Single Screw Extruder ManufacturerQingdao cuishi Plastic machinery is a proffesional manufacturer for plastic extruder machinery production.

We could produce various pp pe pvc extruder machine, like plastic pipe extruder, pp meltblow fabric extruder, pp sheet / pp strap extruder etc.

PPR PE pipe production/extrusion line / PPR PE pipe making machinery is used to produce PPR pipes for cold and hot water supply in house. It's composed of vacuum feeding machine, hopper dryer, single screw extruder, mould, make line co-extruder, vacuum calibration and cooling tank, extended spraying cooling tank, haul off machine, printer, cutter and stack bracket.

The optimum spiral structure-feeding throat highly improves the output of extruder;Accurate temperature control system ensures materials melting performance;Unique screw design achieves better plasticizing and high-quality products;Precisely designed gearbox with a high torsion guarantees stable running;"H" shape frame to decrease vibrating of extruder;Advanced PLC operation system realizes synchronization and automation;Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks;Offer stable haul-off unit with 2-12 caterpillars;Provide saw & chip-free cutting options;Low energy consumption, excellent performance, and easy maintenance.

SJ75/38 single screw extruder

Single Screw Extruder big capacity

There is 45/33,65/30,65/33,75/30,75/33 SJ75/38 ... etc extruders according diameters and ouput.High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality pipe extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel>940, the surface of screw is chromeplated Feeding bush with water cooling system

Main advantages:1. Barrier type screw, by which the material can get good plasticizing at low temperature but high extrusion output.2. Barrel with feeding groove, material is 38CrMoAl and nitrogen treated, surface hardness is HRC 65-68, which can has a long use life.3. Millipore type mould with suitable inner compression ratio which can guarantee to produce high quality PPR PE pipes.4. High automatic level. The production line is controlled by PLC(touch screen). All parts, like extruder, haul off unit, cutteretc can be controlled by touch screen synchronously.

The characteristics:1. Installed with imported termo controllers, imported inverters or converters.2. Hardened gear reducer box, carburized and grinded teeth, installed with forced cooling system to ensure high-performance, low noise and long service life3. For the material feeding section of barrel there're slotted bushing and smooth grooves, two designs to meet the needs of different raw materials.4. Screw and barrel made of nitrided 38CrMoALA wear resistant, corrosion resistant, high strength.5. We also can provide a variety of exhaust-type extruder.

pp pe one layer or thress layers pipe making machineextrusion mold advatages:

- High-speed molds and sizing sleeves

- The inner and outer layers are separated by two 65 extruder, this way can better control the layering. also be used for different purposes, such as three layers of different materials or different colors

CS series Vacuum calibration Tank, SUS304 with spraying painting or pure SUS304 body is for option.Available sizes for different pipe diameters from 16mm upto 800mm.Equipped with famous and high-quality vacuum pump and water pump with overload protection; water temperature auto controlling.4/6/8/10/12 cooling tubes installed inside of the Tank, with ABS sprayers.5meters, 6meters, 9meters and other lengths for option, according to different pipe pressure requirements.

Products Features

1. High toughness and good seismic performance;

2. The connection is reliable;

3. Low density, light weight, easy to handle and install

4. Can resist a variety of chemical media corrosion;

5. Excellent hydraulic performance, the wear resistance coefficient is only 0.009;

6. Long service life, up to 50 years;

7. Good hygiene and environmental performance;

8. Better resistance to slow crack growth (SCG) and rapid crack propagation (RCP).

Deeply trusted and praised by customers.our cuishi company has many subsidiaries such as plastic pipes equipment, sheet/board/film intelligent equipment, intelligent automation equipment, and granulation equipment. We are familiar with kinds of plastic raw materials to help you choose the most suitable machine on best quality by economically.The main products of the company are:1. PVC/PP/PE wood plastic production lines2. PVC/PP/ PS /WPC wide sheet board production lines3. PVC/UPVC /WPC door and window profiles, ceiling panels, wall panels, window sill panels, wall hanging panels and other profiles extrusion production lines4. PC/PA/ABS /TPV /TPE and other profiles production lines5. PVC/PPR/PE/PERT/PC pipe production lines6. HDPE/PE/PVC/PPR/PERT solid wall pipe production lines, as well as HDPE/PE gas pipe production lines7. Vertical and horizontal HDPE/PP/PVC corrugated pipe production lines & reinforced winding pipe production lines8. Multi-layer and single-layer PE/PP/PS/HIPS/GPPS/PC/ABS/PLA/PET/PMMA/APET/PETG sheet production line9. EVA/POE/PVB/SGP film production line; TPU/TVB film and lithium battery separator production line10. All kinds of PE/PP/PLA/PET pelletizing units11. PVC/PE/PP automated centralized feeding system12. PP meltblown fabric and various Spunbond non-woven fabric production lines13. SPC LVT PVC Floor Production Line14. PVC foamed board extrusion production lines

- PP hollow sheet line 16. Recycling auxiliary equipment related to extrusion line, such as extrusion mold, plastic shredder, plastic crusher, plastic pulverizer, cooling tower, automatic screw loader, hopper dryer, plastic mixer and etc.

Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 20 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Brazil, Romania, etc. The company has a high-quality talent R&D team and more than 24 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 200 sets of high-end plastic extrusion lines are produced every year.Qingdao cuishi plastic machinery co.,ltd has advanced design concepts in the extrusion field, strives for perfection in product quality, and continues to improve in technology. It can provide customized solutions for each customer to meet the different needs of customers. Project planning, product positioning, plant planning, equipment installation and commissioning, customer staff training, equipment after-sales maintenance and other all-round services. Our advantage is to provide customers with desired, satisfactory, and high-quality products to help customers create the greatest Profits and business opportunities, customer success is our ultimate goal.

re-sale service:To help customers do market research, make project planning, and production line matched requirements analysis. After-sale service:To provide installation and test for the machine.To provide formulas and technology of relevant products.To provide information on chemical material manufactories.To provide technical training for clients' employees.To direct technology aspect of relevant use according to customers' requirements

- Q: Why can we make plans in one day?

A: We have more than 24 years of experience in designing and producing plastic extruders, which can help you realize your ideas quickly.2.

Q: Are you an industrial factory or a foreign trade company?

A: We are an industrial manufacturer of plastic extrusion machinery and auxiliary equipment located in jiaozhou, qingdao ,China.3.

Q: Where is your loading port?

A: Loading port: qingdao port by sea or train.4.

Q: Payment term:A: T/T, L/C, Western Union or cash, etc.5.

Q: Do you have other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers' requirements.6.

Q: How do you quote for customers?

A: The price depends on the quality and performance, but customer satisfaction is the first priority.7.

Q: How many engineers are there?

A: We have more than 5 professional engineers working and they all have passports.8.

Q: What if the machine is started before delivery? Is it free or do we need to pay?

A: Of course, we have to start the machine for you to check until you are satisfied with our machine and it is free

Plastic Pert HDPE PPR Hot/Cold Water and Drainage Pipe/Tube Extrusion Making/Machine

Warranty: 1 year.You just tell me what machine you want,let us do the rest work:

1. Design and manufacture suitble machine for you.2. Before delivery, we will test the machine until you are completely satisfied. (You can come to our factory to inspectthe running production line.)3. Delivery.4. We will provide after-sales service: (1) Field installation and commissioning; (2) Field training your workers; (3) Field maintenance and repair service ;(4) Free Spare Parts ; (5) Video/Online technical support.Prev: Housingless Mill Stand From Fuzhou City/ Steel Rolling Mill

Next: Factory Price Hot Rolling Mill for Tmt Bar, Rebar, Deformed Bar, Wire Rod Mill Production Line

Our Contact