Automatic Hot Rolling Mill Production Line for Steel Deformed Rebar/ Tmt Bar Making Machine

Description

Basic Info

| Model NO. | GOYO-R-001 |

| Layout | Open Train |

| Type | Hot Rolling Mill |

| Certification | ISO, CE, CCS, Lr, ABS |

| Function | Steel Rolling |

| Technology | Technology |

| Delivery Time | 60 Days |

| Key Selling Points | High Productivity |

| Applicable Industries | Manufacturing Plant |

| Colour | Cutomized |

| Advantages | Large Output.High Efficiency |

| Transport Package | Wooden |

| Specification | Customization |

| Trademark | GOYO |

| Origin | Guangzhou |

| Production Capacity | 600000t/ Year |

Product Description

Automatic Hot Rolling Mill Production Line for Steel Deformed Rebar/ TMT Bar Making MachineProduct Description

Full rolling process

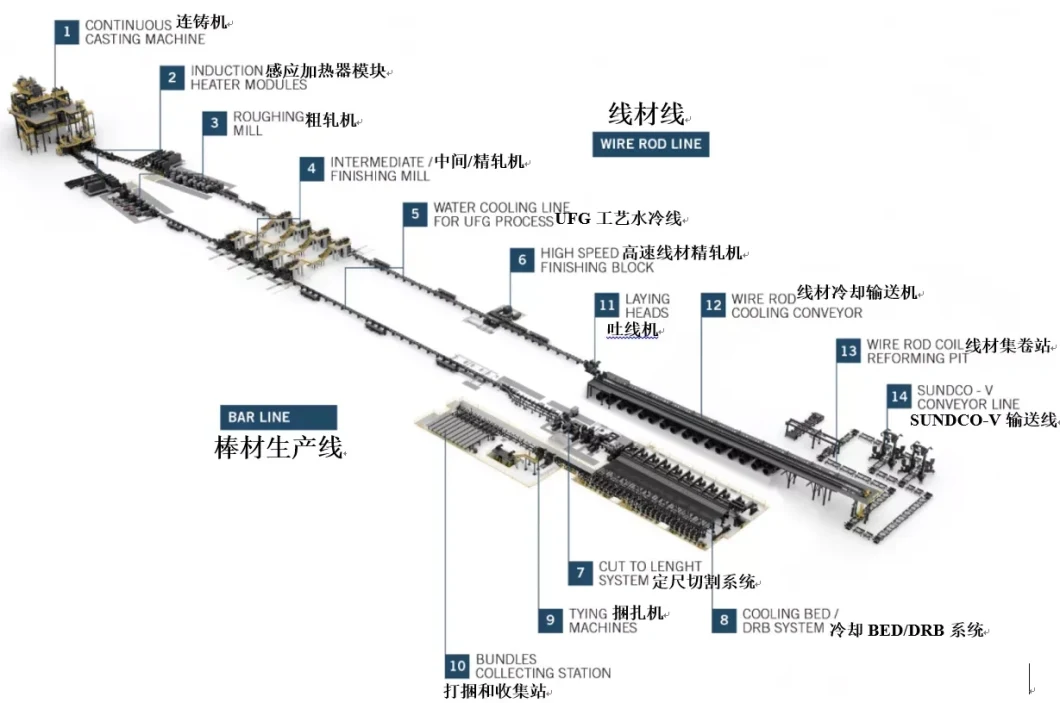

High-speed Wire Rod Mill Production Line Lay Out

Process Flow: (Scrap steel melting furnace, continuous casting machine, billet heating furnace) Reheating furnace→ Roughing mil l→ Intermediate mill→ 3#Flying shear → Pre-finishing mills → Mono Block Mills/Finishing Mill → 3#Flying shear → Finishing rolling mill → Pinch roll → Laying head→ Cooling → Collecting → Packing → Labeling → Weighting → Storage

High-Speed Wire Rod Mill Production Line

High-speed Wire Rod Mill Production line with annual capacity: 500,000.00 tons, automatic continuous rolling mill applied.Input Billet size: 150*150*12000mm steel billet Finished Product Specifications: Ø5.5~14mm Wire Rod

Rolling speed: 80m/s

Guarantee Speed: 50~60m/s

Arranged after the No.3 flying shear area and before the cooling device.

Its role is to continuously micro tension rolling by 6 rack unit, the rolled piece diameter 10.4~14.8mm of rolling mill upstream delivery, rolled into 5.5 ~ 12mm finished wire rod.

Unit to ensure exit speed of 56m/s. Finishing mill group 1 set.

The total of finishing mill is 8 stands, made of 152 rolling mill, all arranged with top cross 45 type.

The finishing mill train is combined with 6 stands, made of and 152 rolling mill, and with Morgan type.

Rolling Mill Type | High-Speed Wire Rod Mill Mill Production Line |

Input Material | 150x150x12000mm Steel Billet |

Steel Grade | High/Low Alloy Steel, Structure Steel, Carbon Steel |

Rolling Speed | 50~60m/s meters/second |

Finished Product Size | Wire Rod: Ø5.5mm~14mm Length: 12000mm |

Annual Capacity | 500,000 Ton/Year |

Our Advantages

MODULE MILL advantages:

1.Speed up, increase production:When rolling Φ6, normal roll speed is 75m/s, one hour production is 57t, used module mill, speed increase to105m/s, one hour production is 78.76t.

2.Reduced alloy composition:Production of fine grain rebar, billet cost decreased 80/t

3.Shorter time to change the roll:Shorter time to change the roll, annual production increased 2,880,000t.

4.Reduce equipment storage:Only one bevel gear box is needed as a reserve, can reduce 4, at 2 million yuan per unit, the reserve can be reduced by 8 million yuan

5.Motor:Main motor power in DC motor reasonable power range, can choose DC transmission scheme, saving investment of RMB 3 million.

6.Energy Saving:According to the field test, the empty power consumption of each mill is as high as 100kw. According to the production of four empty mills, the annual waste of electricity is as high as 2.24 million KWH (7000*8*400=2240000), and the electricity cost is 1.344 million yuan (224000*0.6=1244000).

7.Less Spare Parts:The inventory of roller rings, guide guards and other technological parts shall be reduced by more than 4 million yuan.

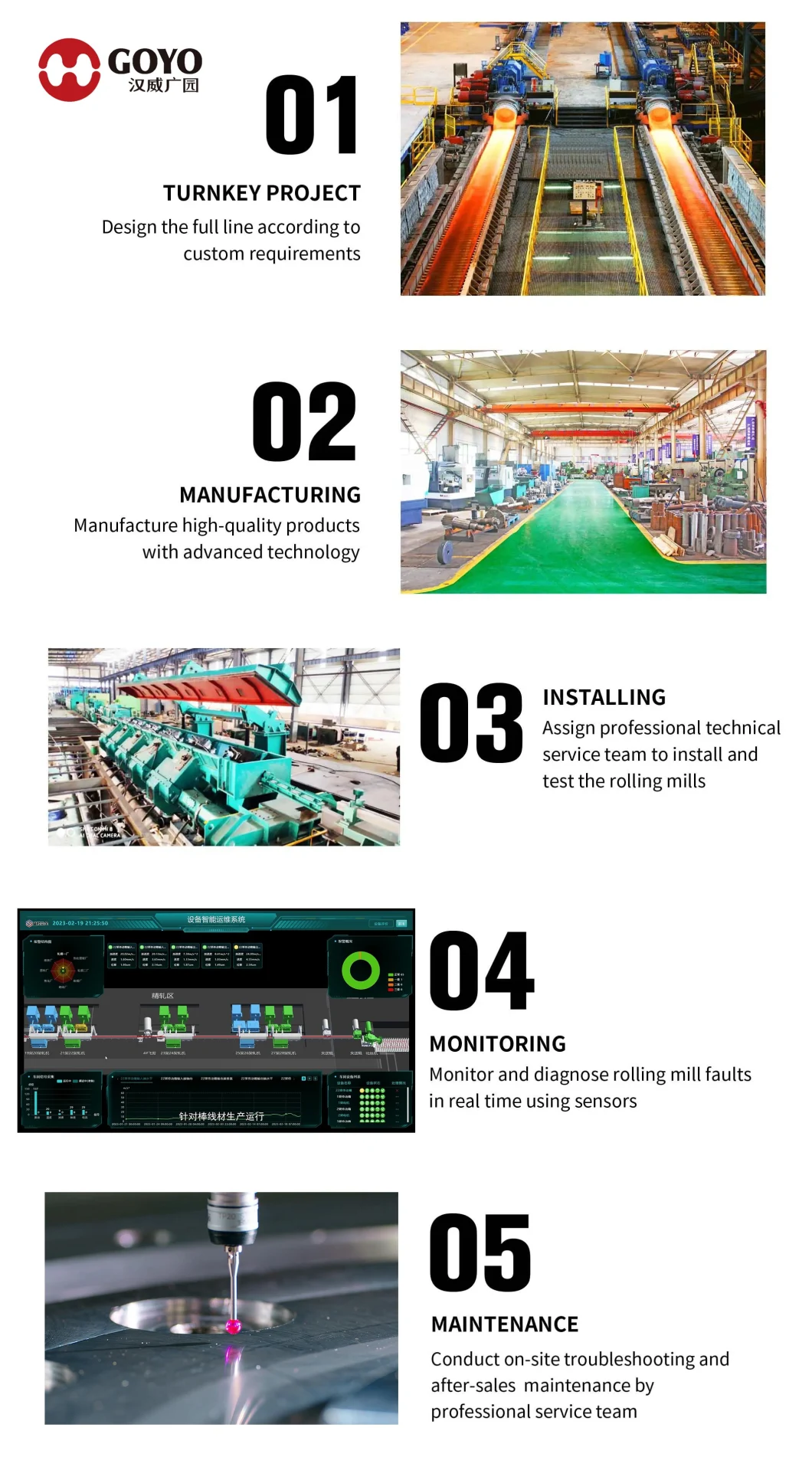

Our Services

Company Profile

FAQ

Are you a trading company or a manufacturer?

We are a professional rolling mill manufacturer with 29years of experience supported by the chinese government. We offer tailor made high speed wire rod and bar hot rolling mill product solution and turnkey project.

How many successful projects have you done?

Since 1996, GOYO's products and services have been exported to more than 20 countries and regions, such as China, Malaysia, Russia, Thailand, South Africa, India, Ethiopia, Philippines, Vietnam, Indonesia and so on.How do you guarantee quality?Quality is our lifeline.GOYO has a complete quality assurance system and an excellent quality management team. We insist on pre-production samples before mass production and final inspection and trial operation before shipment;At the same time, we have obtained the international ISO, BV and SGS quality system certification.How to get a quote?Please tell us the following details by email or other means, so that we can recommend suitable plans and layouts to you:Turnkey project or part of equipment or partsRaw material (bill or scrap) and its sizeFinished product and its dimensionsWhether a furnace is required and what fuel is usedYour planned annual output and working hoursAvailable factory areaPlease let us know if you have any additions or questions.

Our Contact