20mm-110mm Glassfiber PPR Pipe Making Machine/PPR Pipe Production Line/PPR Tube Machine

Description

Basic Info

| Model NO. | Glassfiber PPR |

| Engagement System | Full Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Line Speed | 30m/Min, 20m/Min, 15m/Min |

| Pipe Diameter | 20mm-63mm, 20mm-110mm |

| Pipe Ratings | Pn20, Pn25 |

| Control System | Siemens PLC Control |

| Electrics Components | Schneiders |

| Frquency Inveter | ABB Brand |

| Gravimeter System | Kaide Brand |

| Each Layer Thickness | Free Adjusted |

| Servo Motor | Siemens |

| Overseas Service | Engineer Overseas Service Available |

| Transport Package | 1X40 Feet Container |

| Specification | 28m/min |

| Trademark | KAIDE |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 200sets Per Year |

Product Description

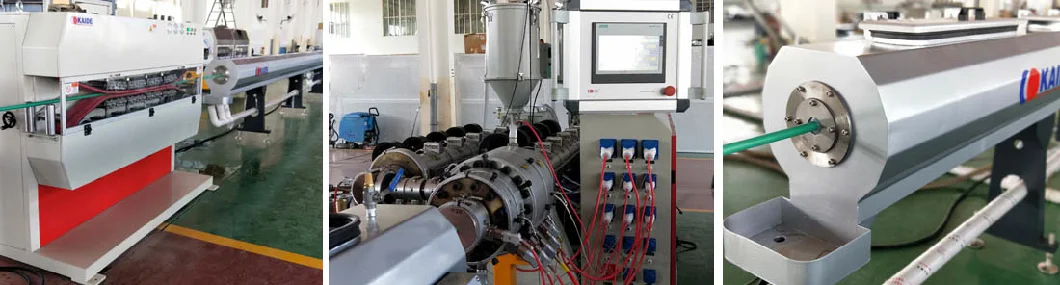

High Speed Glassfiber PPR Composite Pipe Production Line. The glassfiber PPR pipe making machine adopts the specialized high efficient wear-resistant extruderfor glass fiber reinforced plastic material, which ensures high speed extrusion and guarantee the long service life of extruder.

Production Line Consists:

| No. | Machine set composition |

| 1 | PPR Pipe Extruder |

| 2 | Glassfiber PPR Pipe Extruder |

| 3 | Stripes Extruder |

| 4 | Vacuum Calibration Tank |

| 5 | Cooling Tank |

| 6 | Servo Haul-off Machine |

| 7 | High Speed Cutting Machine |

| 8 | Pipe Stacker |

| 9 | Siemens PLC Control System |

Technical Data

| Line Model | Screw Diameter | L/D | Production Scope | Production Speed | Nominal Power |

| SJ-75 | ф60/65mm | 36/33:1 | ф20-63mm | 30m/min | 258KW |

| SJ-60 | Ф60/65mm | 36/33:1 | ф20-63mm | 20m/min | 165KW |

| SJ-65 | ф65/45mm | 33:01:00 | ф20-63mm | 15m/min | 119KW |

Gravimeter System

(1 )High precise Gravimeter control system of is applied in this glassfiber PPR pipe production line.

(2) It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

(3) The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

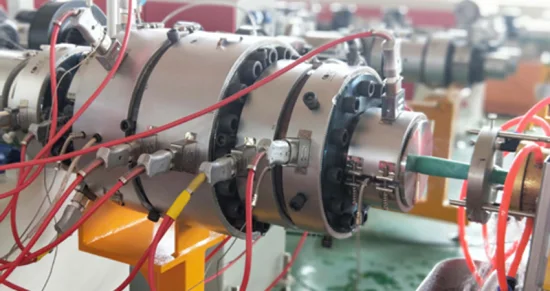

Co-Extrusion Die Head

(1) Patented speciallydesigned adjustable co-extrusion die head, can ensure even thickness of threelayers,

(2) Each layer thicknesscan be adjusted freely; no need to adjust the extruder's rotating speed.

Haul-off machine

(1) The haul-off machine adopts structure of high speed multi-group roller clamping type.

(2) Completely overcomes the vibration & skip problems in the traditional mode, ensuring high-speed stable pulling.

PLC Control System

(1) The three layers glassiber PPR pipe machinery adopts original imported new generation PLC control system.

(2) Multi-point closed-loop control system, which ensure the high speed synchronous control and reliable operating of the whole production line.

Advantages of Glassfiber PPR Pipe:

(1) The linear expansion coefficient is only about 20 ~ 30% of ordinary PP-R products, which completely solves the problem of plastic pipe expansion.

(2) The rigidity of the pipe is enhanced to prevent the pipe from sagging, and the density and quantity of the fixed support points are reduced, so as to reduce the comprehensive cost of the project.

(3) It has higher withstand voltage level and longer service life under normal design shaking force.

(4) FR / PP-R is applied in hot water system, the normal service temperature can reach 95 ~ 100 ºC, which not only improves the temperature of medium, but also reduces the thickness of insulation material, and its comprehensive cost is lower.

(5) Large water flow: under the same level of pressure, the wall thickness of FR / PP-R pipe is thin, which increases the inner diameter of the pipe, thus increasing the water flow (by 20%).

(6) The problem of oxygen permeability of the pipeline is solved. The inner surface directly in contact with water is sanitary, non-toxic, good sealing and will not form water moss. The glass fiber reinforced FR / PP-R pipe is composed of an intermediate layer, which completely insulates the outside air from penetrating into the pipe, so as to inhibit the growth of algae and keep the water fresh and pure.Hot ProductsCompany ProfilePackaging & ShippingFAQ1.Are you manufacturer or trading company? We are manufacturer.2. What price terms you offer? FOB, CIF, EXW and other price terms based on your kind request.3.Is installation and stuff training available from you? Yes, our engineers will guide machine installation and train your workers.4. How long will I receive the quotation? Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 24 hours.5. How do I get response quickly?If you send inquiry to contact us, we promise to reply to you within 8 hours!

Our Contact