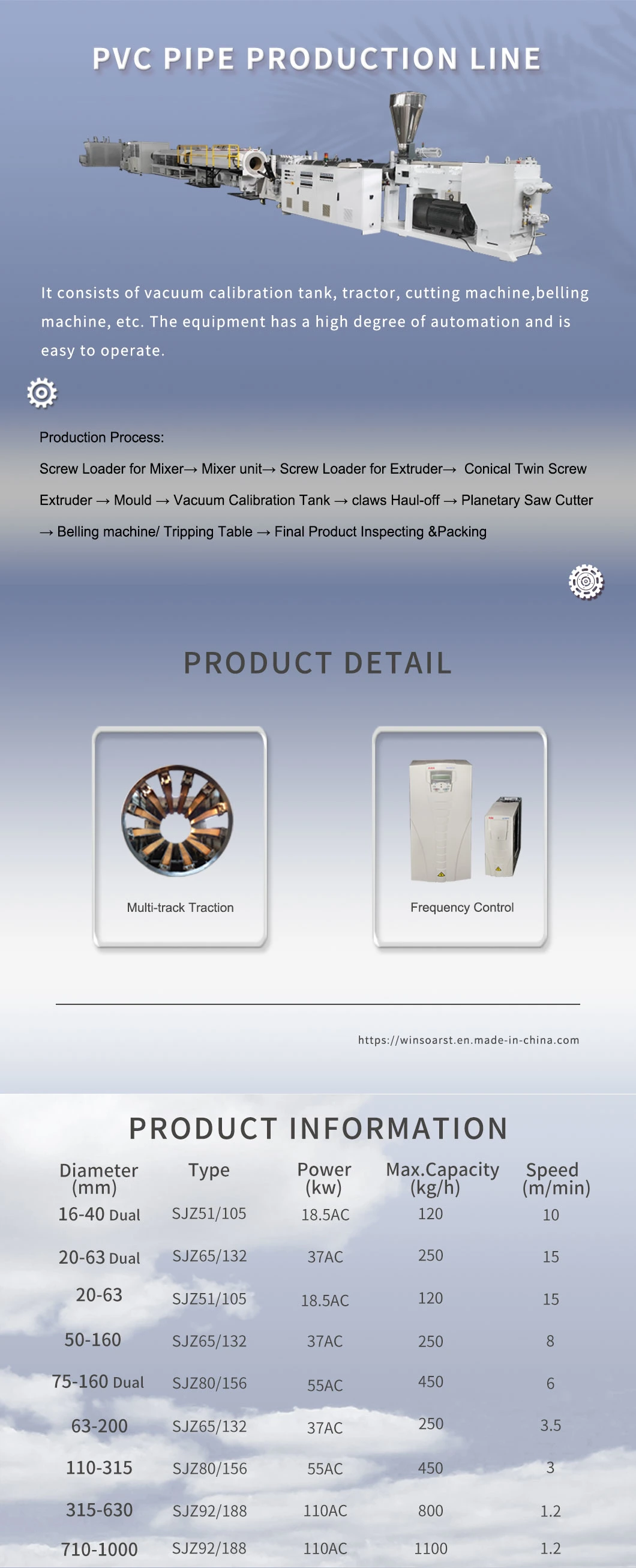

Plastic PVC/CPVC/UPVC Water& Electric Conduit Pipe/Tube (extruder, haul off, cutting winding, belling) Extrusion/Extruding Making Production Line Machine

Package size per unit product 3000.00cm * 300.00cm * 250.00cm Gross weight per unit product 8000.000kg Φ20-Φ630 series P

Description

Basic Info

| Model NO. | WS005 |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Customized | Non-Customized |

| Condition | New |

| After-sales Service | 7*24hours |

| Delivery Time | 20-50days |

| Voltage | Customizable |

| Color | Customizable |

| Electronic Parts | ABB/Siemens/Omron/Rkc |

| Gurantee | 1 Year |

| Motor | Siemens |

| Transport Package | Seaworthy Packing |

| Specification | 16-800mm |

| Trademark | WINSOAR |

| Origin | China |

| HS Code | 8477209000 |

| Production Capacity | 400sets/Year |

Packaging & Delivery

Package size per unit product 3000.00cm * 300.00cm * 250.00cm Gross weight per unit product 8000.000kgProduct Description

Φ20-Φ630 series PVC pipe extrusion machine line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing, cable laying etc. This line is composed of conical twin screw extruder, Vacuum calibration tank, haul off, motors, cutter and stacker etc. The extruder and haul off methods are two-claw, three-claw four-claw, six-claw, eight-claw, ten-claw, twelve claw etc. You may choose saw blade cutting type or planetary cutting type. It is addition attached with length counter and intensifying device. This line with reliable performance and high production efficiency. Our company can also manufacture special pipe production lines,e.g. spiral silencing pipe and core foaming pipe according to your requirements.PVC pipe making machine has the following features:

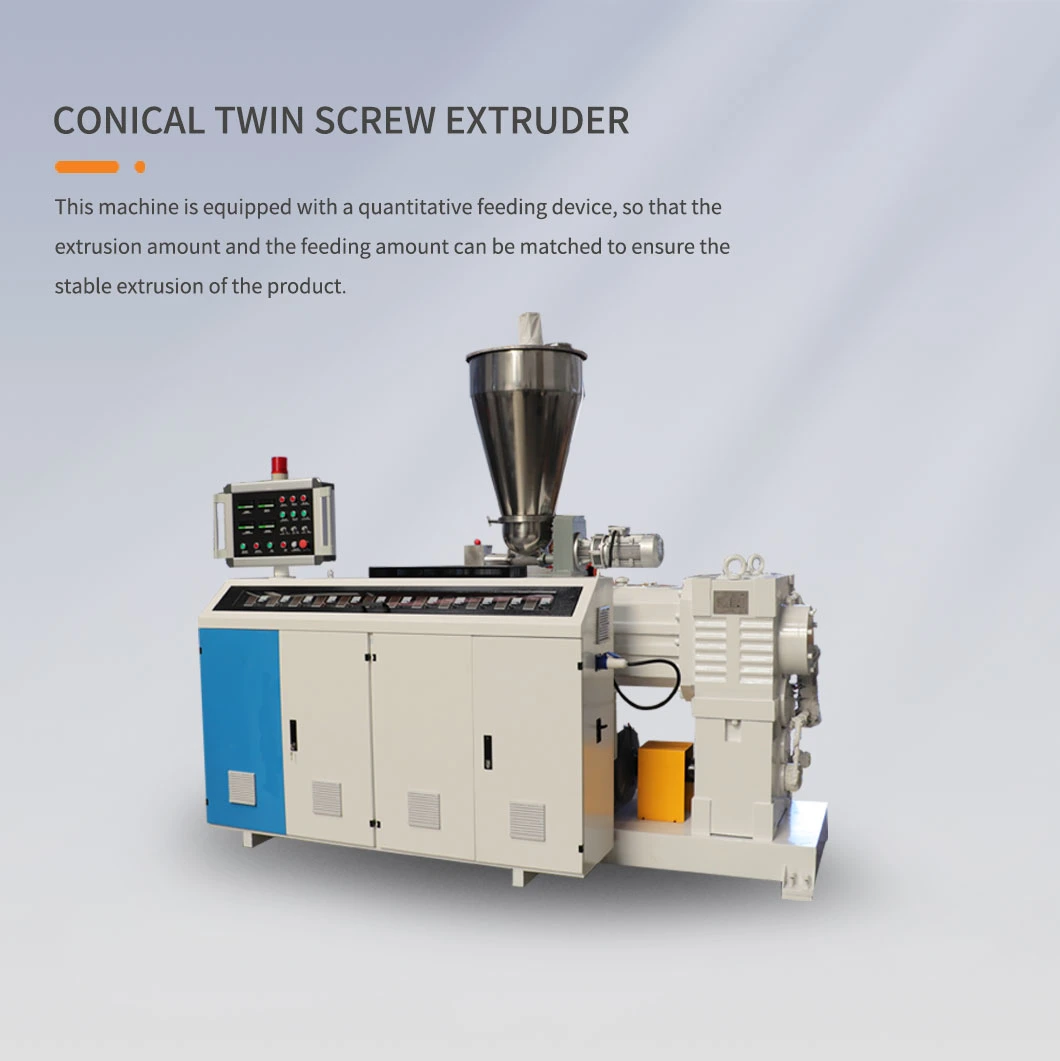

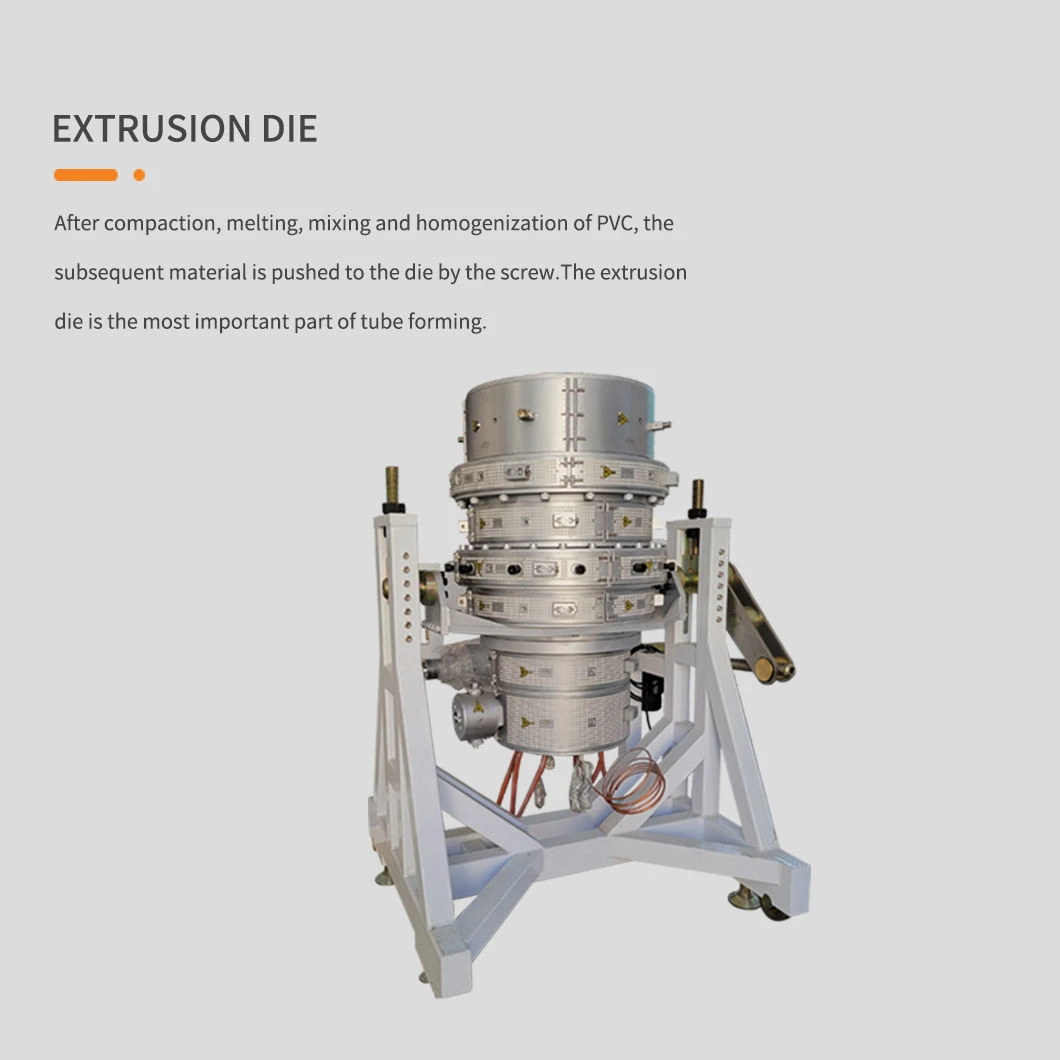

1.Extrusion Equipment of PVC pipe making machine :Double screw extruder takes the new and efficient Screw, and has the higher screw speed, yield and plasticizing capacity...nose or spiral-flow nose, with a uniform material, convenient adjustment to eliminate extrusion fusion line and so on.

2.Vacuum shaping devices of PVC pipe making machine :vacuum spray tank, spray cooling tank or efficient cooling tank, and all water contact parts made of stainless steel material.

3.Traction machine of PVC pipe making machine :two claw-type or rubber belt crawler tractor in order to adapt to different pipe production requirements..

4.Cutting machine of plastic pipe making machine :No dust rotating knife.

5.Stacking devices of PVC pipe making machine :automatic turn plate or roller-type stacking devices, small-diameter pipe can be configured duplex winder according to customer requirements duplex winder.

6.Electrical control system for a variety of options (eg: PLC automatic control system),good production speed, stability, and the control system is simple and easy to operate.

Diameter Range (mm) | Extruder Type | Extrusion Power(KW) | Max. Capacity (kg/h) | Max. Haul Off Speed(m/min) |

Ф16-40 Dual | SJZ51/105 | 18.5 AC | 120 | 10 |

Ф20-63 Dual | SJZ65/132 | 37 AC | 250 | 15 |

Ф20-63 | SJZ51/105 | 18.5 AC | 120 | 15 |

Ф50-160 | SJZ65/132 | 37 AC | 250 | 8 |

Ф75-160 Dual | SJZ80/156 | 55AC | 450 | 6 |

Ф63-200 | SJZ65/132 | 37 AC | 250 | 3.5 |

Ф110-315 | SJZ80/156 | 55 AC | 450 | 3 |

Ф315-630 | SJZ92/188 | 110 AC | 800 | 1.2 |

Ф710-1000 | WSP130/26 | 160 AC | 1100 | 1.3 |

Our Contact

Send now